Description

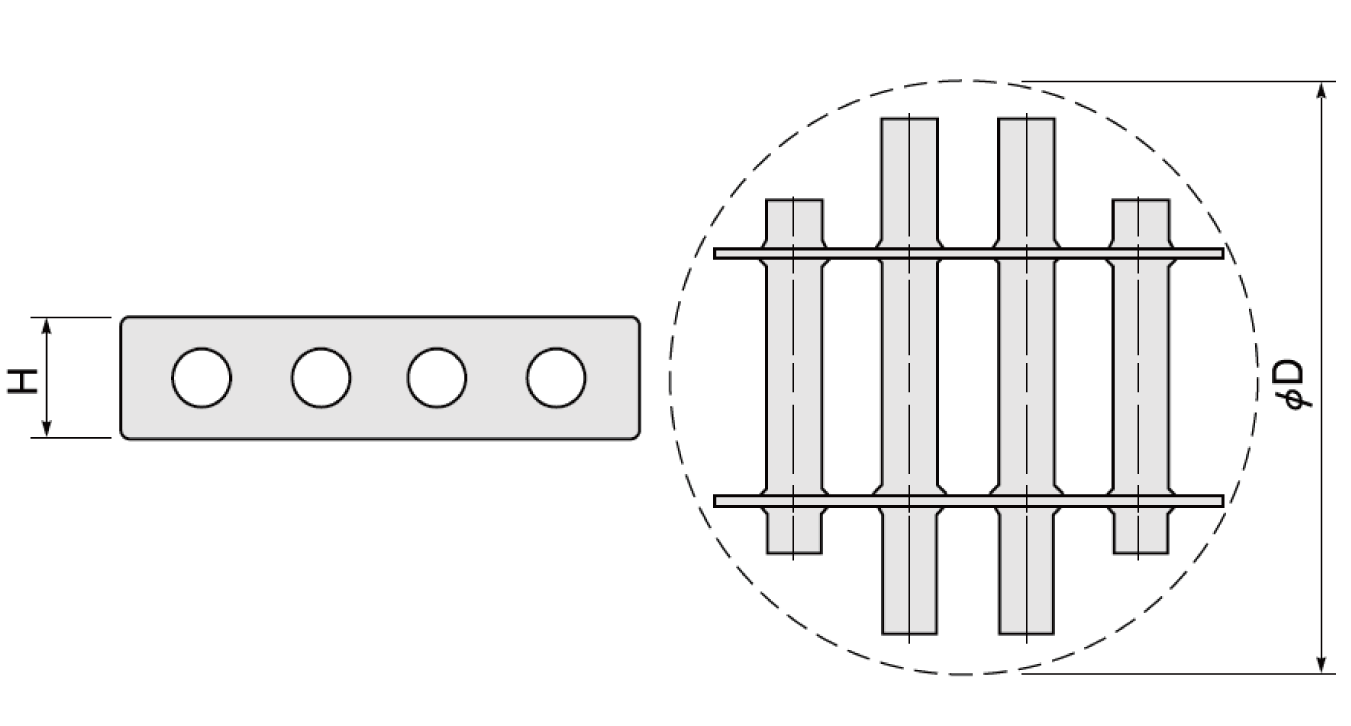

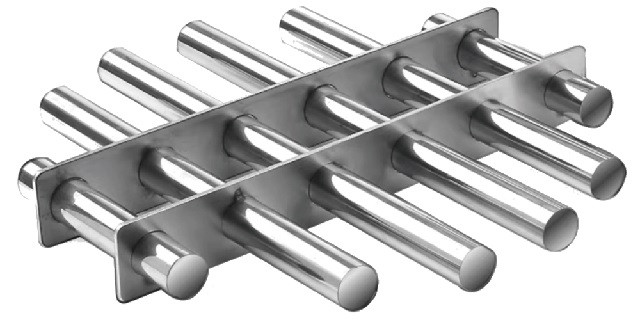

Magnetic gratings are primarily designed to be installed in hoppers for the extraction of ferrous metals from the material being processed. They can be made into any size or shape by simply placing them in a hopper leaning against the side, allowing the material to flow through a magnetic grid for the rigorous filtering process typically used in the plastics industry.

In order to improve the capture rate, double-row and more than three-row magnetic grilles can be manufactured. All magnetic grates are manufactured with powerful rare earth magnets that can extract fine ferrous material such as rust. Single magnetic bars are also available with end drilled and tapped according to your requirements.

Like most magnetic separators with an easy-to-clean system, the magnetic grille can also be cleaned by pulling out the sleeve, and ferrous metal contamination on the surface will spontaneously fall off.

Structural Features

1. The magnetic grid is composed of burning rods, and the surface magnetic field strength can be above 1000-14000 Gauss.

2. The surface is made of SUS304, SUS316 or SUS316L stainless steel tube welded and polished, which can be used to process dry powder, wet or liquid materials.

3. The surface has been mirror polished, which can meet the requirements of food hygiene level.

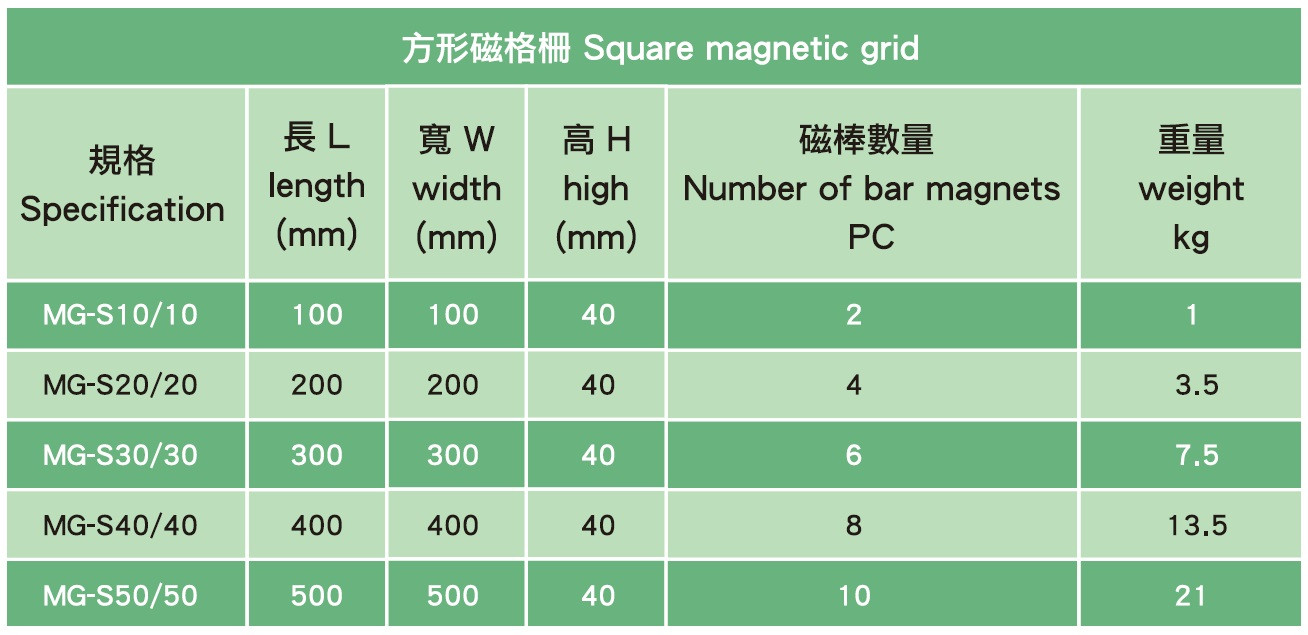

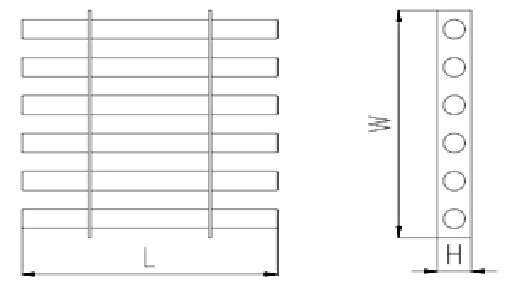

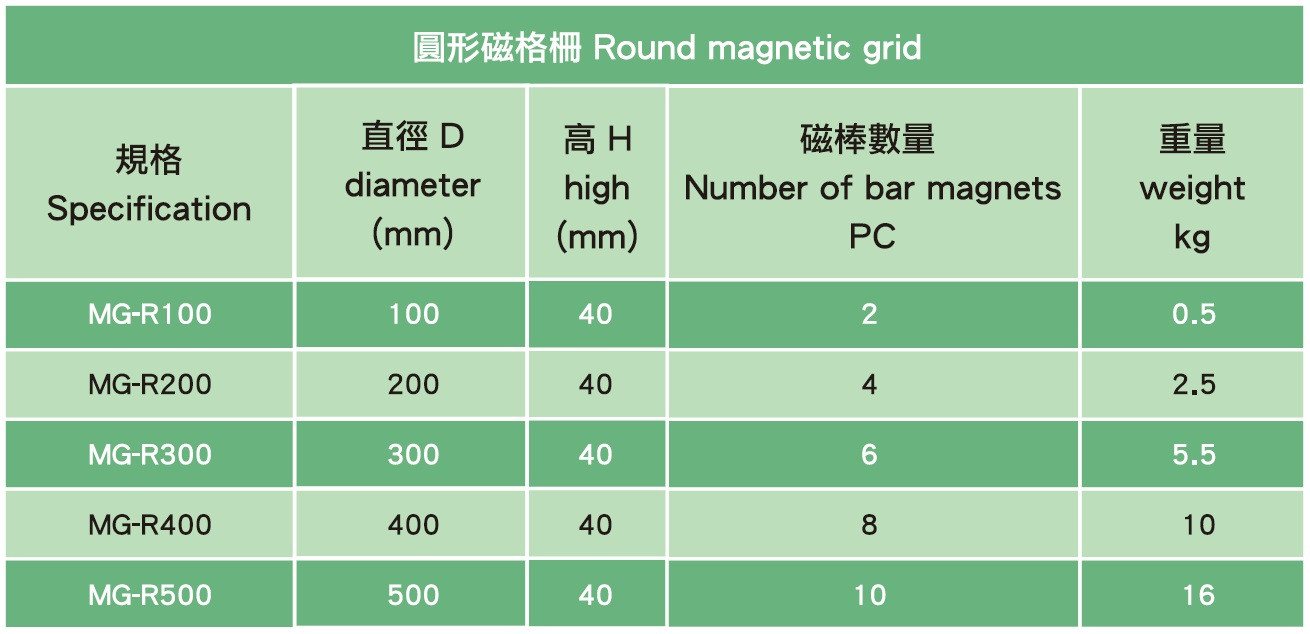

4. The magnetic grid can be customized according to customer requirements, such as square or rectangular, round or irregular shapes.

5. The working temperature of conventional products is greater than or equal to 80 °C. According to specific use requirements, it can be made with temperature resistance of 100 °C, 120 °C, 150 °C, 180 °C, 220 °C, 250 °C, etc., the highest Up to 350 °C.

6. The two ends of the magnetic grid can be made into threaded holes, screw rods, hanging rings, tapered tips, etc. according to requirements, which is convenient for fixed installation.

Special Magnetic Grids

※This product can be customized

※This product can be customized