Description

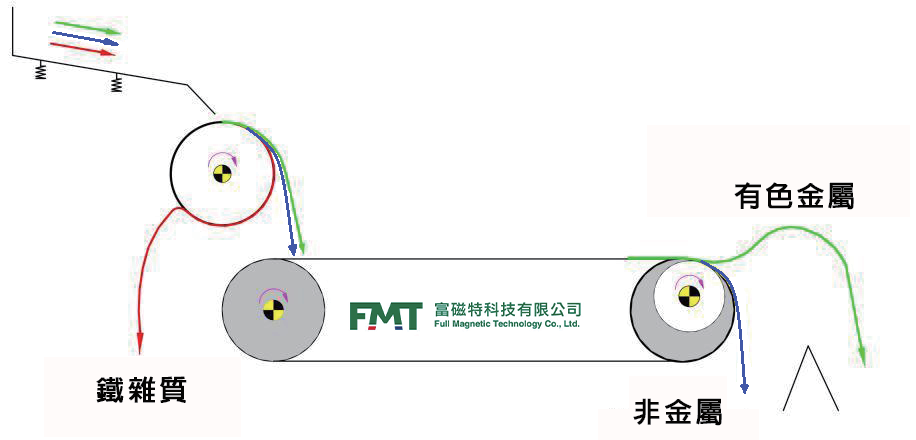

When the non-ferrous metal eddy current sorting machine is working, a high-frequency alternating strong magnetic field is generated on the surface of the sorting magnetic roller. When conductive non-ferrous metals pass through the magnetic field, eddy currents are induced in the non-ferrous metals. This eddy current itself A magnetic field in the opposite direction to the original magnetic field will be generated. Non-ferrous metals (such as copper, aluminum, etc.) will leap forward along their transport direction due to the repulsive force of the magnetic field, achieving separation from other non-metallic substances and achieving the purpose of sorting. Purpose; The main distinction criterion is the ratio of the material's conductivity and density. The lower the ratio, the more difficult it is to distinguish.

Eddy current separators are suitable for

1. Sorting, smelting and casting aluminum and copper.

2. Remove the aluminum cover from recycled glass waste and classify aluminum and aluminum alloys.

3. Collect aluminum or copper blocks from the block.

4. Collect non-ferrous metals from incinerated printed circuit boards.

5. Separate and collect aluminum cans from municipal waste.

6. Separation of copper, aluminum, zinc, lead, Non-ferrous metals.

2. Remove the aluminum cover from recycled glass waste and classify aluminum and aluminum alloys.

3. Collect aluminum or copper blocks from the block.

4. Collect non-ferrous metals from incinerated printed circuit boards.

5. Separate and collect aluminum cans from municipal waste.

6. Separation of copper, aluminum, zinc, lead, Non-ferrous metals.

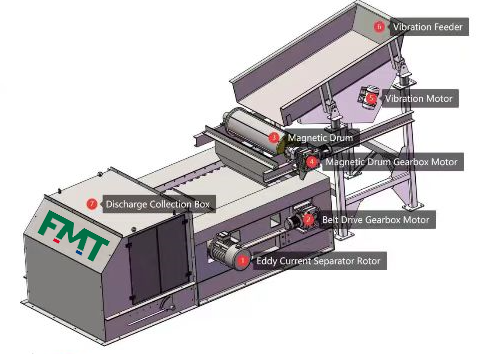

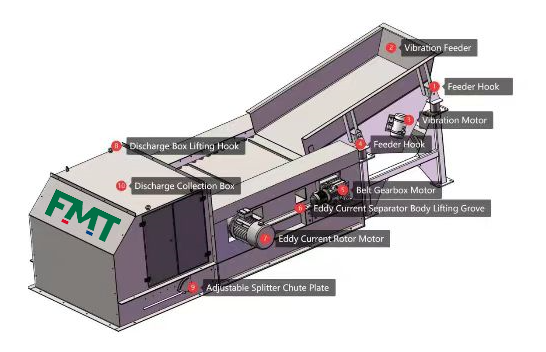

Features of eddy current separator

•Advanced eccentric rotor design

•Optimized design of rotor magnetic system distribution, multi-pole high field strength to achieve optimal sorting effect.

•The speed of the rotor and conveyor belt is adjustable, making it easy to adjust according to on-site conditions and optimize sorting.

•Electronic control system that can be equipped with touch screen and equipment monitoring sensors.

•Complete models, effective sorting belt width range 50-200 cm.

The eddy current sorting machine is not suitable for magnetic material sorting. Too much magnetic material entering the eddy current sorting stage will cause serious damage to the equipment.

cause damage. Iron removers, magnetic drums and other sorting equipment can be used to remove iron before the materials enter the eddy current sorting section.

Application scope of eddy current

•Sorting non-ferrous metals from municipal waste (MS W).

•Separate copper and aluminum from plastic bottle flakes (PET).

•Separating non-ferrous metals from boiler bottom ash

•Recover precious metals from electronic waste (W E E E).

•Separating non-ferrous metals from scrap tires.

•Separate copper and aluminum from glass scraps.

•Separate copper and aluminum from foundry sand.

•Sorting non-ferrous metals from scrapped car scraps (A SR).

•Separating non-ferrous metals from waste energy.

•Sorting non-ferrous metals from wood scraps.

•Sorting non-ferrous metals from waste paper.

•Separating non-ferrous metals from scrap steel crushing materials.

Equipment detail photos

What are the advantages of eccentric and concentric eddy current separators

• The design position of the rotor of the eccentric eddy current separator enables effective and precise separation of non-ferrous metals.

• The eccentric eddy current separator is more optimized for sorting fine materials.

• The adjustable rotor position can be adjusted accordingly to achieve the optimal sorting effect according to different material specifications.

• The concentric eddy current separator has the problem of burn-through. When the material contains iron or ferrous particles and eventually When entering the eddy current sorting area, the eddy current will heat these particles, and the heated iron particles will burn through the belt and The roller will damage the equipment, but the eccentric eddy current separator does not have these problems.The magnetic rotor that affects the throwing angle can be tilted inside the drum to change the moment when non-ferrous metals are thrown out. This means that the rotor position can be adjusted to achieve the best separation effect of material separation.

Institutional design

Eccentric eddy current separator + magnetic drum (materials contain iron impurities)

Eccentric eddy current separator

(materials containing iron impurities)

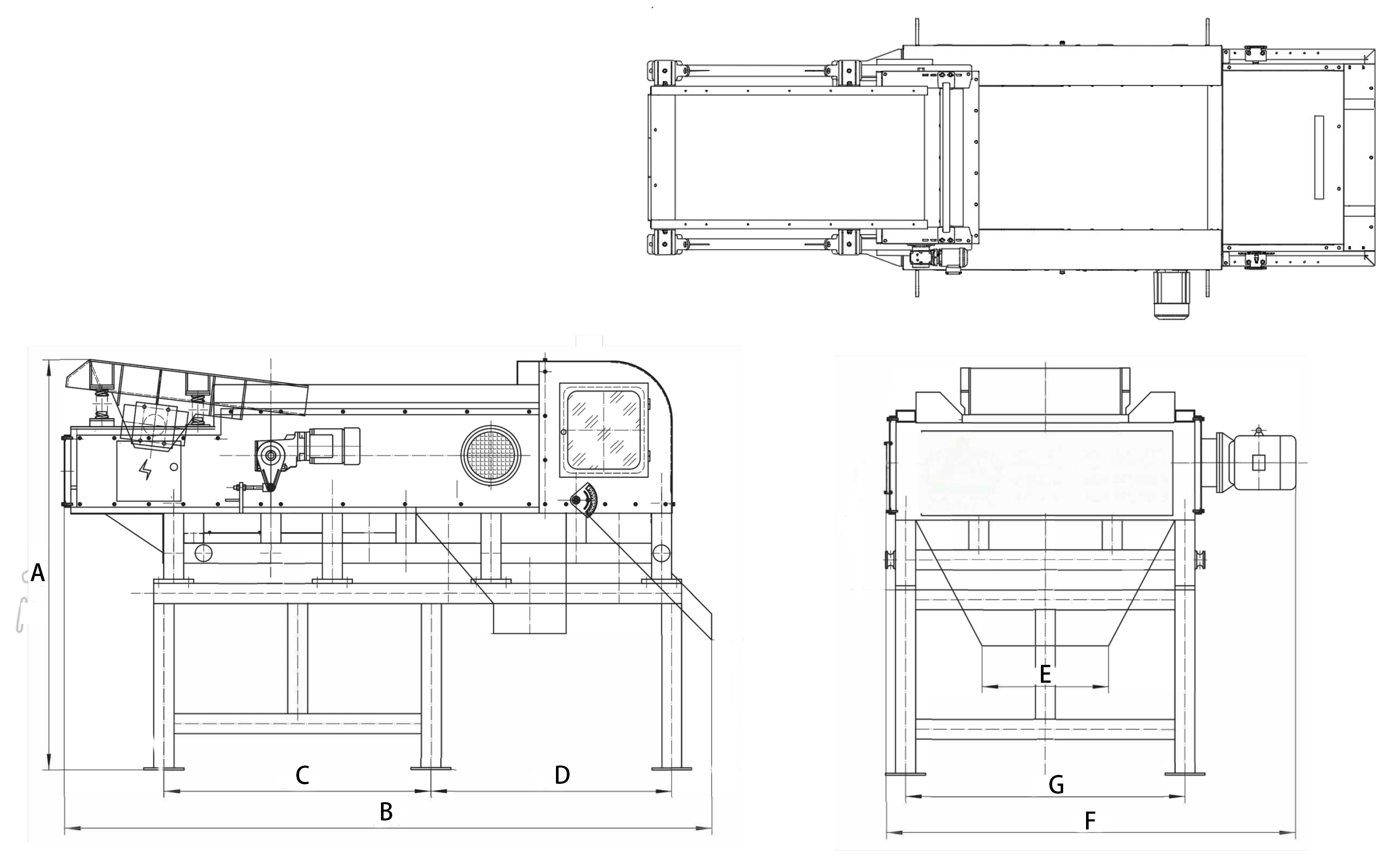

Concentrictechnical parameters:

|

Type

|

Feed

width(mm)

|

Feeding

length(mm)

|

Feed size

(Mm2) |

capactity

(m3/h)

|

power(kw)

|

Weight(kg)

|

overall Dimensions(mm)

LxWxH

|

ESC-5C |

300 |

1500 |

≥25 |

8 |

5.9 |

630 |

4600X1123X1200 |

ESC-6C/6.5C |

400/400 |

1500 |

12/15 |

5.9/5.9 |

795 |

4600X1223/1423X1200 |

|

ESC-8C |

600 |

1500 |

22 |

5.9 |

1120 |

4600X1623X1200 |

|

ESC-10C |

800 |

1500 |

27 |

6.3 |

1450 |

4600X1823X1200 |

|

ESC-12C |

1000 |

1500 |

32 |

7.0 |

1750 |

4600X2023X1200 |

|

ESC-14C |

1200 |

1500 |

37 |

8.8 |

2150 |

4600X2223X1200 |

|

ESC-16C |

1400 |

1500 |

42 |

10 |

2950 |

4600X2423X1200 |

|

ESC-17C |

1500 |

1500 |

47 |

10 |

3000 |

4600X2523X1200 |

|

ESC-20C |

1800 |

1500 |

52 |

10.7 |

3550 |

5000X2823X1200 |

Eccentrictechnical parameters:

|