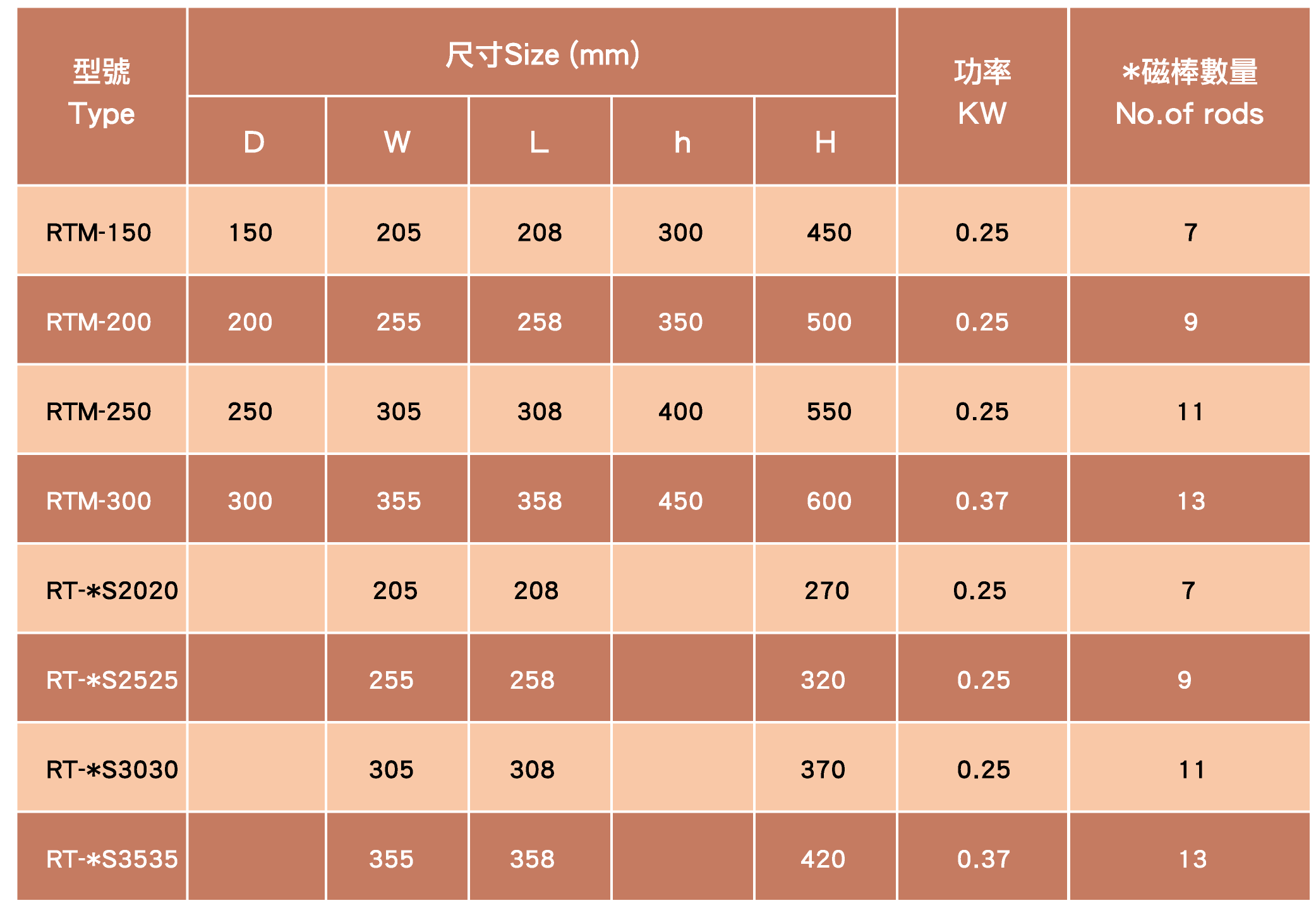

Description

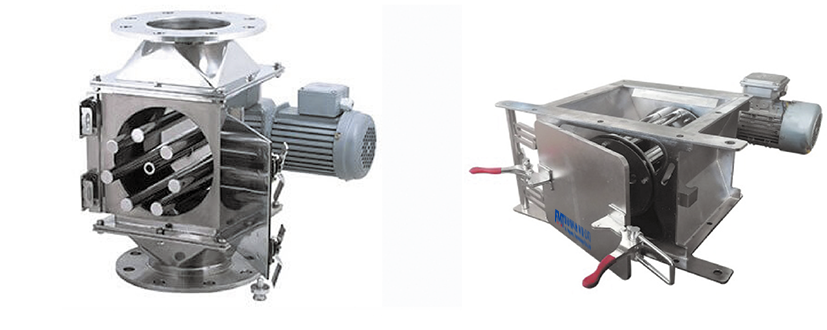

Rotary grid separators are designed to remove ferrous particles from very fine powder streams that can clog and bridge fixed grids. Separate foreign bodies and avoid blockages. The rotating unit is designed in such a way that it moves a powerful bar magnet through the powder flow, increasing the magnet-to-powder contact. It prevents bridging of the product due to the slow rotation. The design allows you to easily clean the magnetic tube by hand and provides an outlet for magnetic contamination. Variable speed control is also available if desired.

Characteristic

1.Surface treatment: mirror polishing, wire drawing or sandblasting.

2.Box material: SUS304, SUS316, SUS316L.

3.Magnetic field level: above 3000Gs, 8000Gs, 1 OOOOGs, 12000, 14000Gs

4.Working temperature: < 80°C; to the highest 350°C.

5.lnstallation method: round and square flange or quick clamp interface.

6.Cleaning method: provide common type and easy-to-clean type for selection.

7.Geared motor: provide relevant parameter requirements, explosion-proof grade, or brand information.

Construct

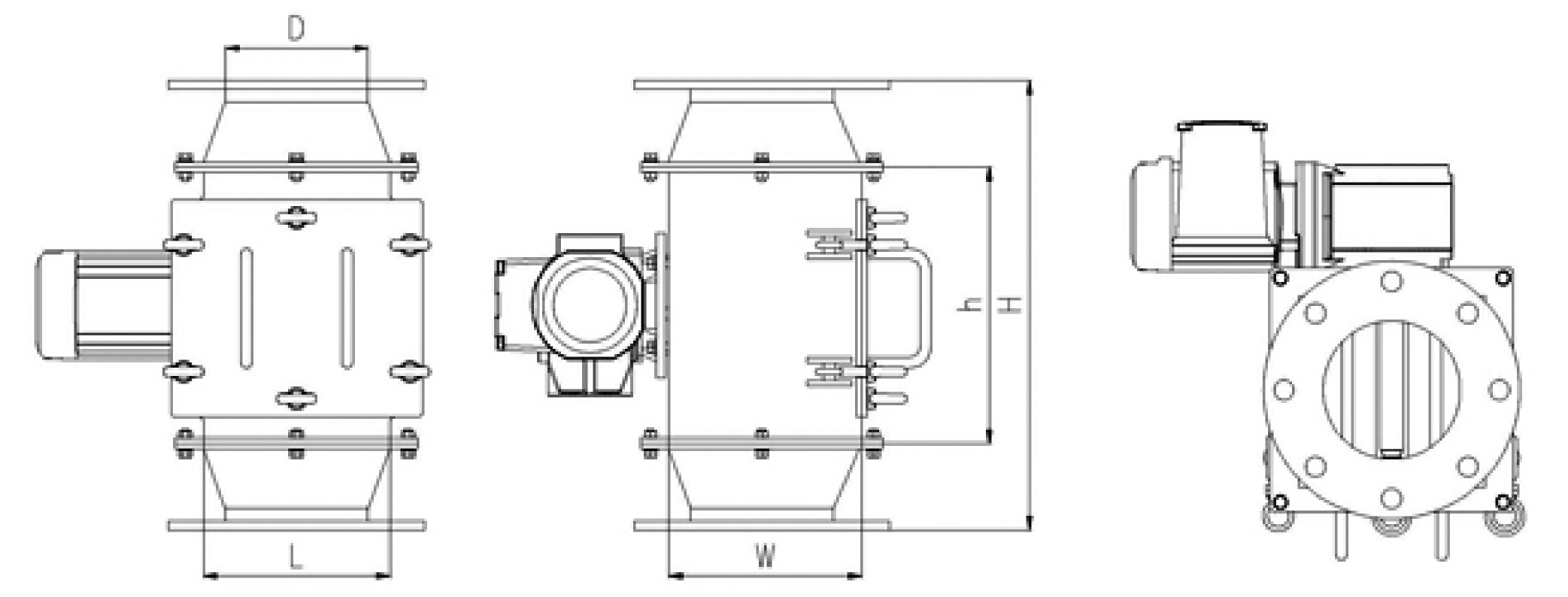

The rotary grid separator is composed of three parts: a ring-shaped magnetic grid, a stainless steel box and a deceleration motor. When the deceleration motor is energized, the ring-shaped magnetic grid in the box is driven to rotate.