Description

The magnetic separator for fluid pipeline is mainly used to filter and remove iron impurities and other magnetic particles in fluid, semi-fluid and other materials of different viscosity, to prevent the contamination of raw materials and equipment, and to ensure the purity of the product. At the same time, it can protect the function of downstream production equipment.

Structural features

1. Surface treatment: mirror polishing or wire drawing treatment or sandblasting, which can reach food grade standards.

2. Shell material: SUS304, SUS316, SUS316L.

3. Magnet: Using high-strength rare earth permanent magnet material, the surface magnetic field can reach more than 14000 Gauss.

4. Working temperature: The standard working temperature is lower than 80°C, and the maximum working temperature is 350°C according to the special needs of customers.

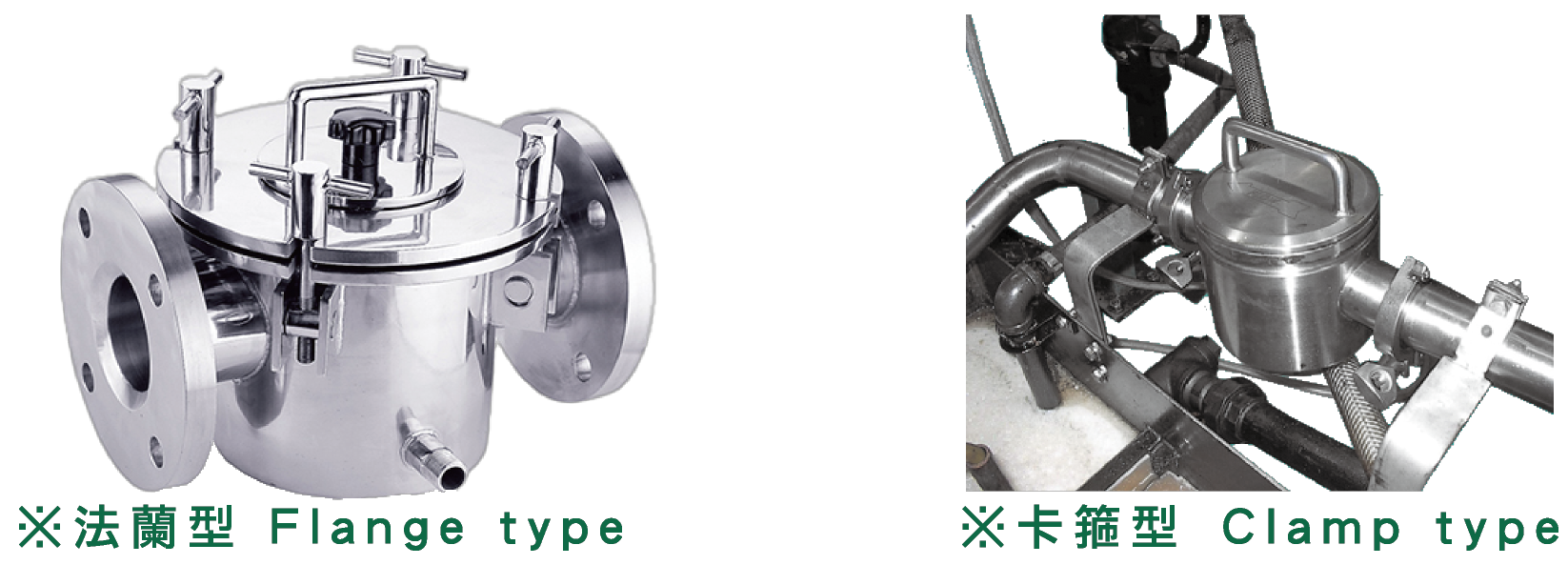

5. Pressure resistance: flange generally ≤10 kg (1.0MPa), clamp generally≤5 kg (0.5MPa). If there are special needs, Can be designed separately.

6. According to the cleaning method, provide ordinary type and easy-to-clean type for Choice.

7. In order to meet the thermal insulation requirements, a design thermal insulation layer can be provided.

8. At the same time, it can be customized according to customer requirements.

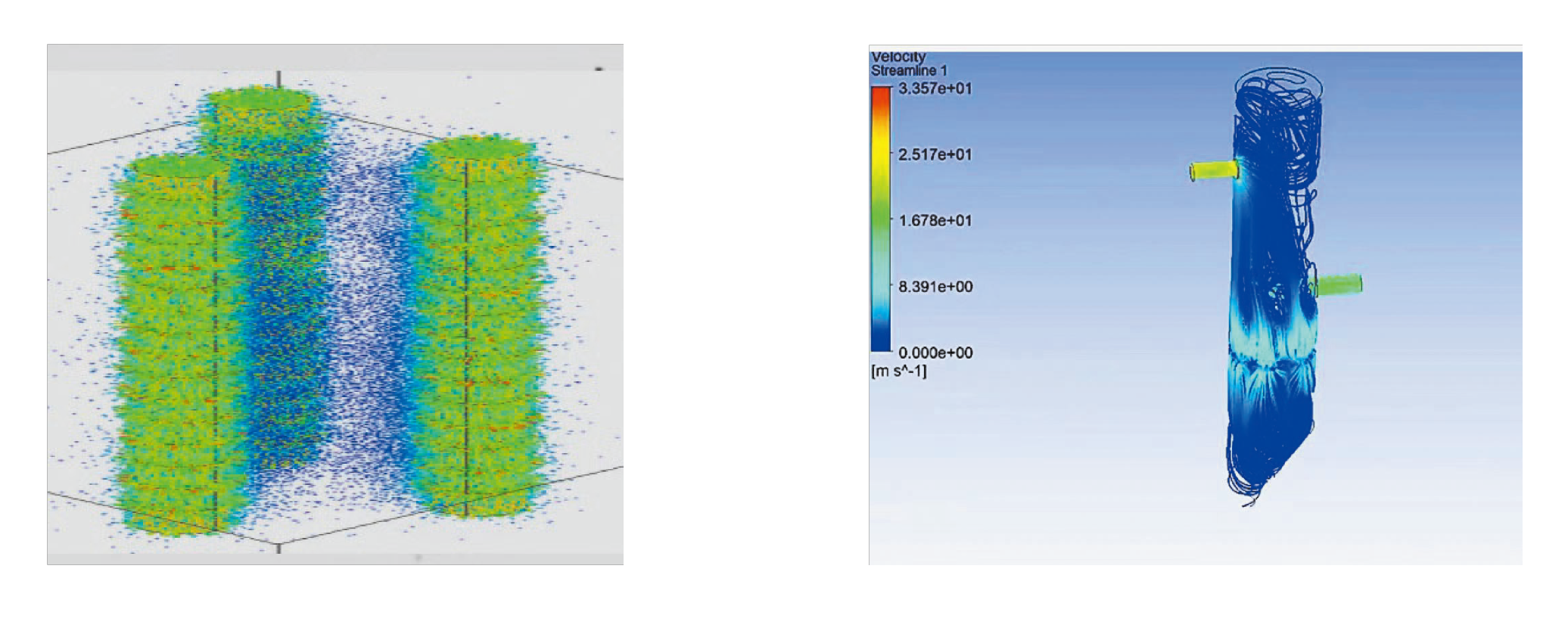

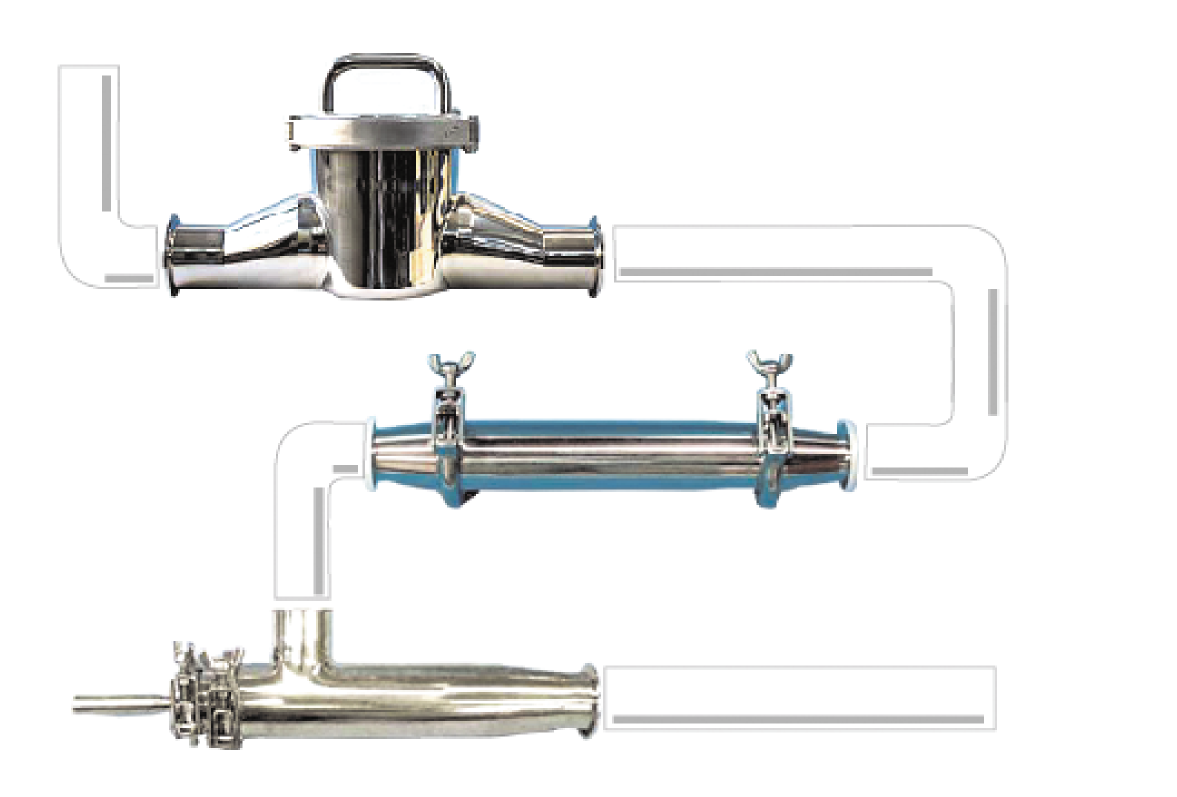

Simulation diagram of water flow in fluid pipeline

1. Insulation Type

Removing iron contamination from liquid and semi-liquid materials of various viscosities, keeping materials pure and protecting equipment. The thermal insulation magnetic liquid iron separator has a sandwich layer, which can be filled with oil and water insulation materials to solve the insulation difficulty of liquid passing through the body. It is perfect for removing ferrous contamination from jams, chocolates, syrups, jams, etc.

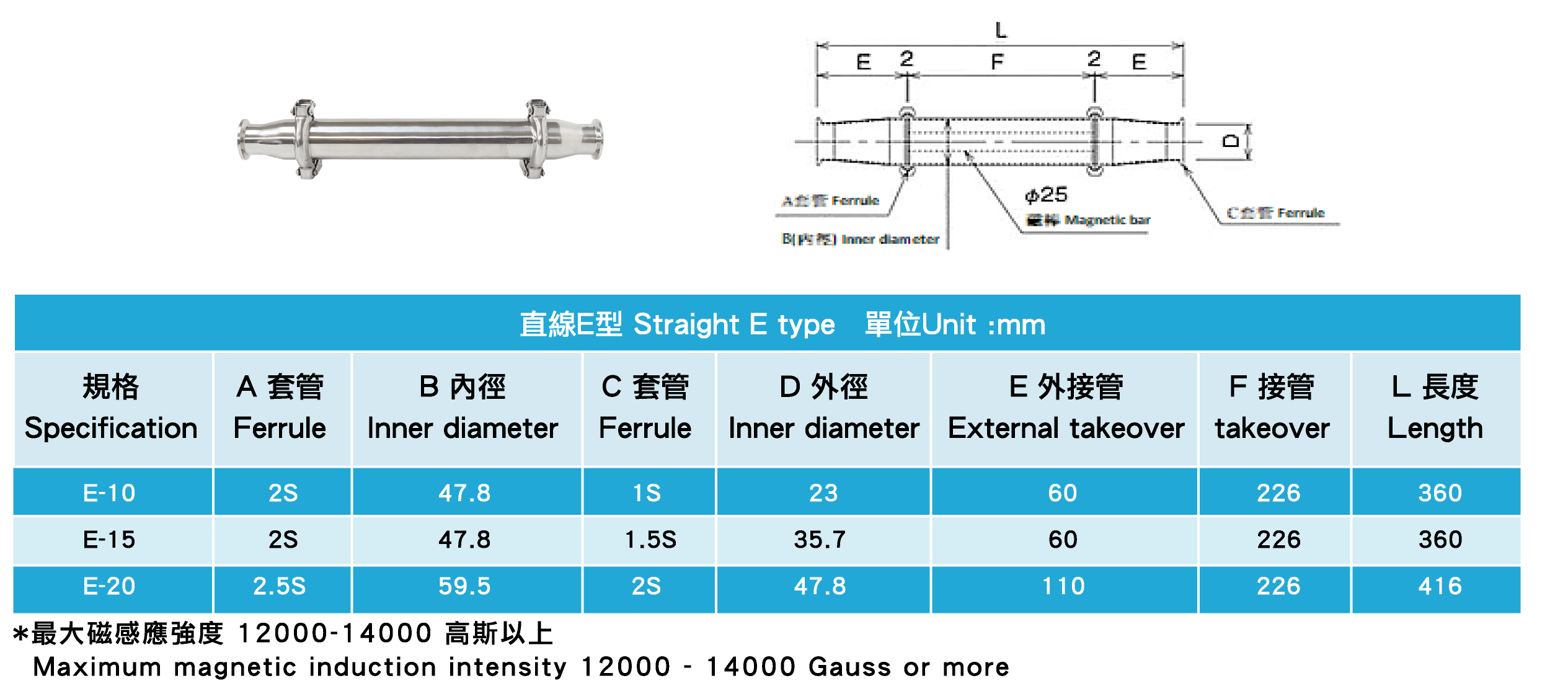

2. Straight E Type

The material flow quickly enters the pipe body under the action of the pressure difference, and the pipe is distributed in a cone shape. The contaminated iron material is adsorbed and held by the magnet when it is close to the magnetic rod, and the clean material product continues to flow out of the body.

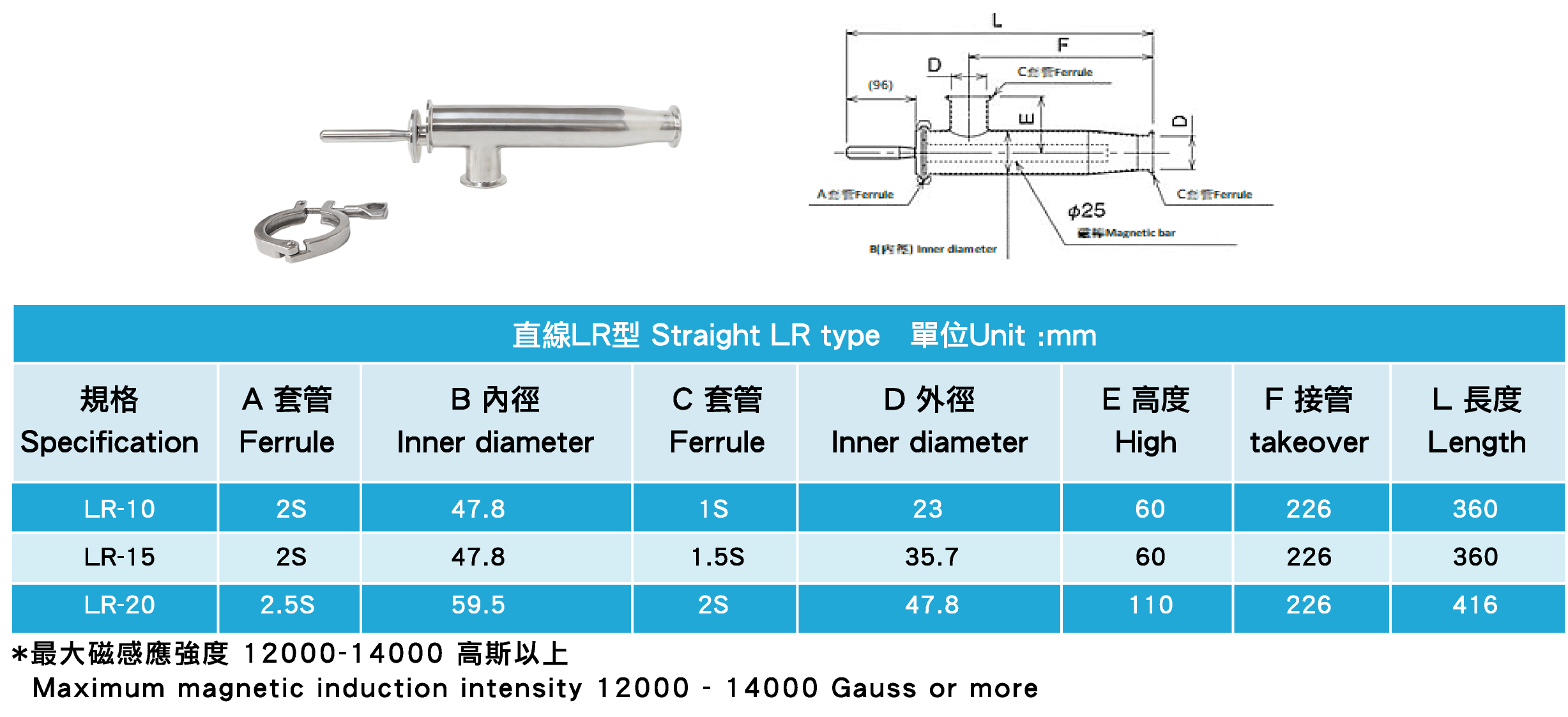

3. Straight LR type

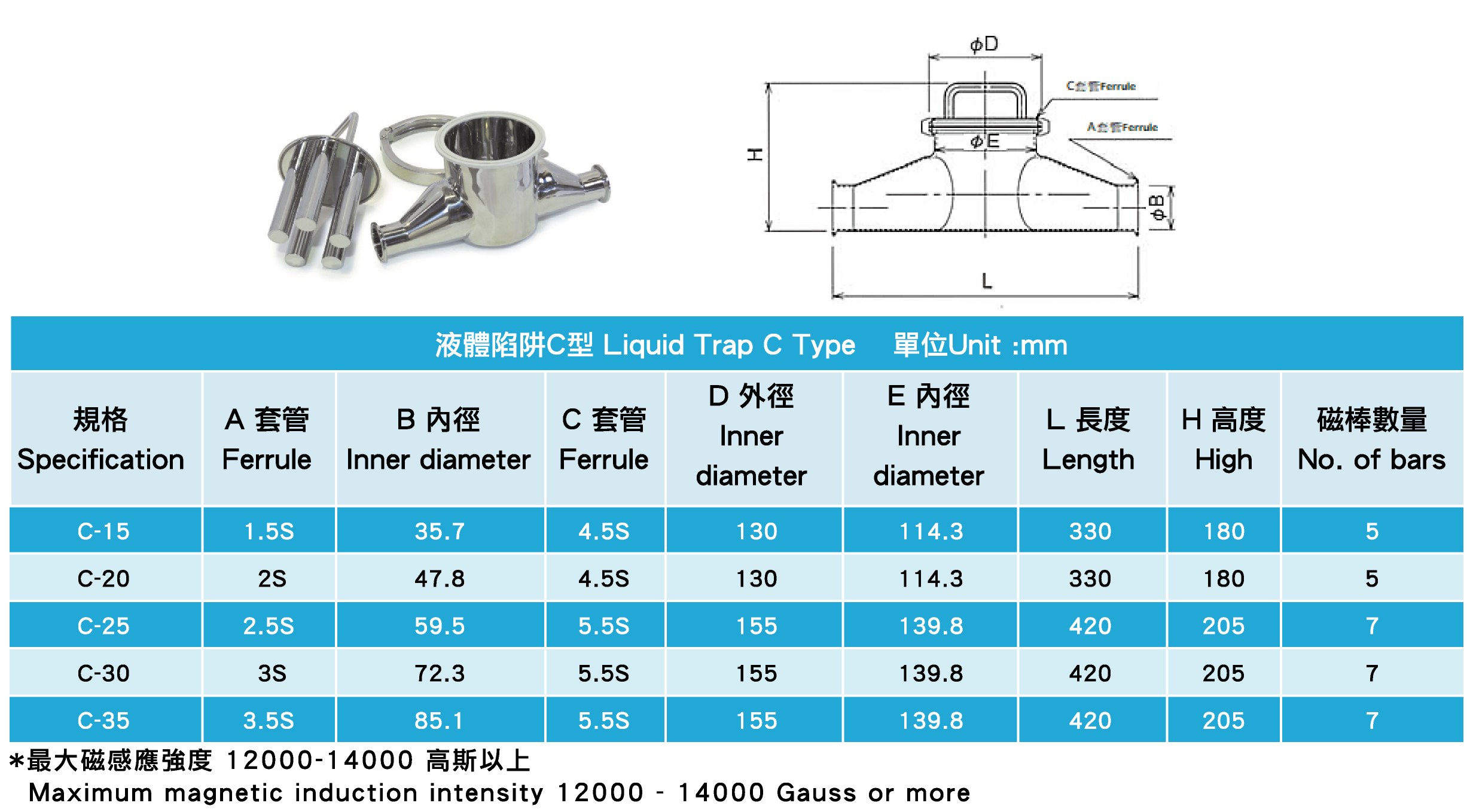

4. LiquidTrap C Type

Schematic diagram of 3 kinds of fluid pipeline iron remover

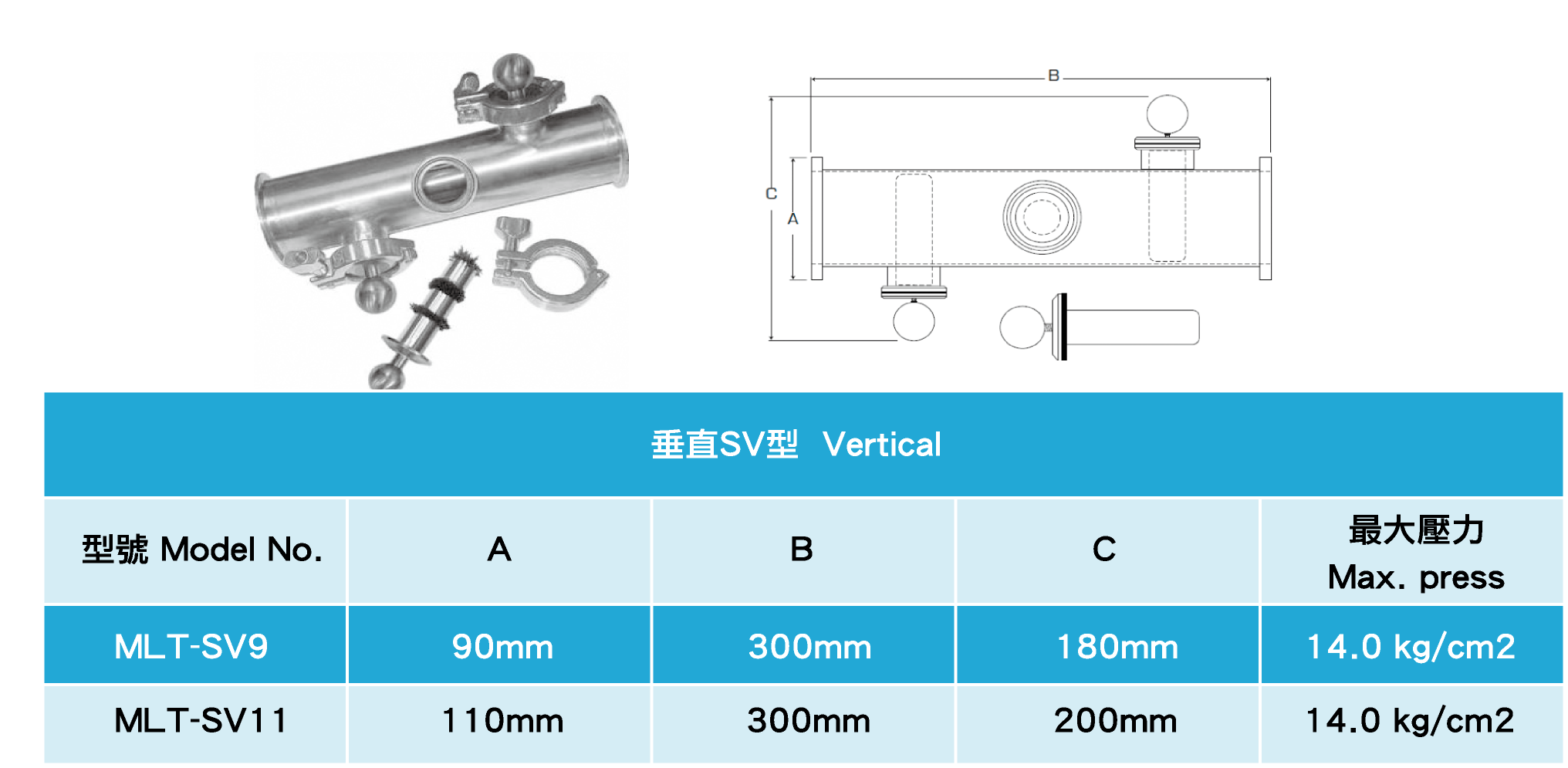

5. Vertical SV Type

Vertical In-Line Iron Separator (SV Series), which effectively controls foreign debris and reduces the risk of capturing tiny metal debris in viscous & slurries and emulsion lines.

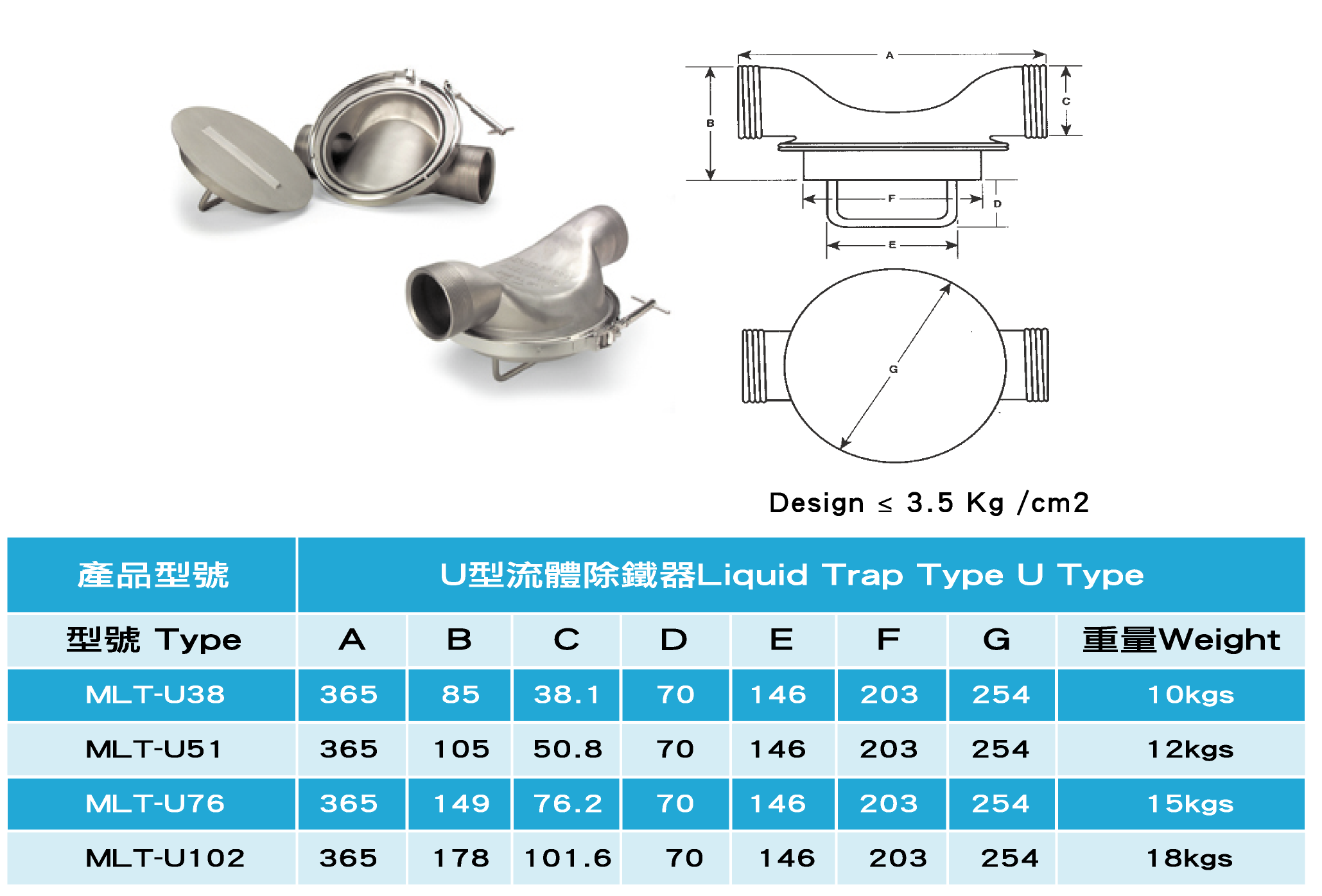

6. Liquid Trap Type U Type

U-fluids use a magnetic field to remove fine ferrous contaminants such as rust, scale or screens. U-fluid removes iron impurities from hard-to-flow or lumpy products such as vegetables, salsa or meat paste.

The special body design of the U-Fluid has a tapering transition that gently guides the product onto the smooth magnetic surface.

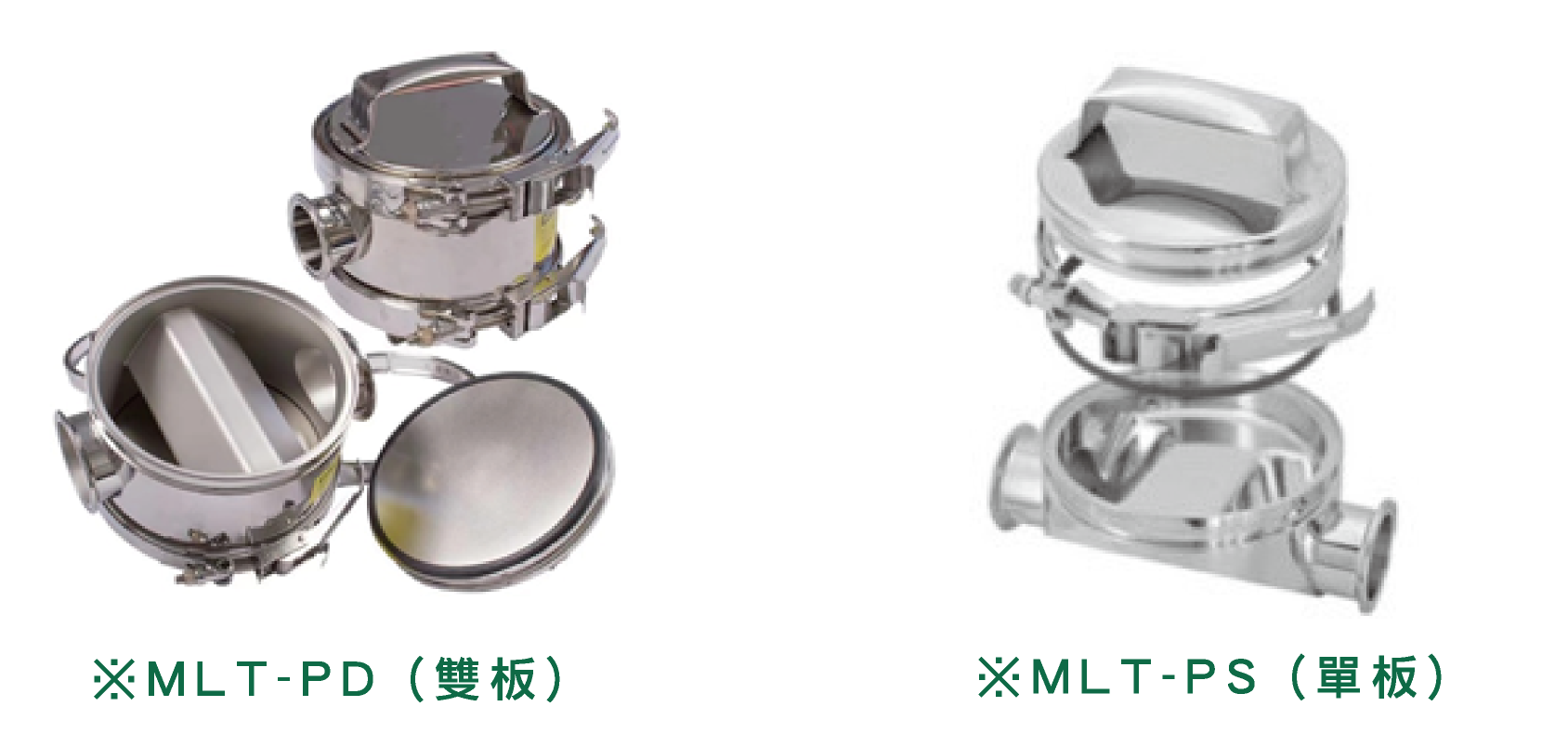

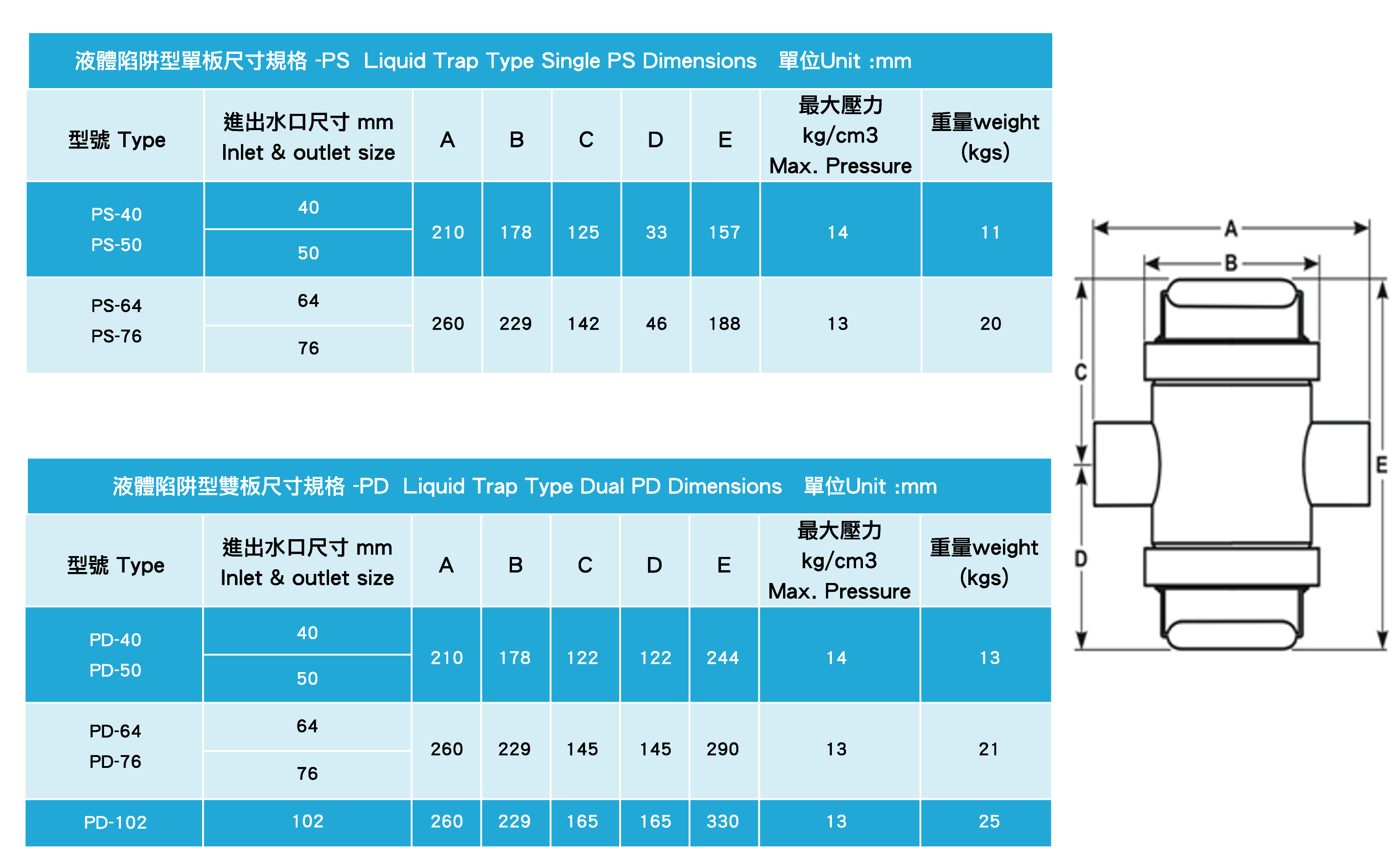

7. Liquid Trap PS&PD Type

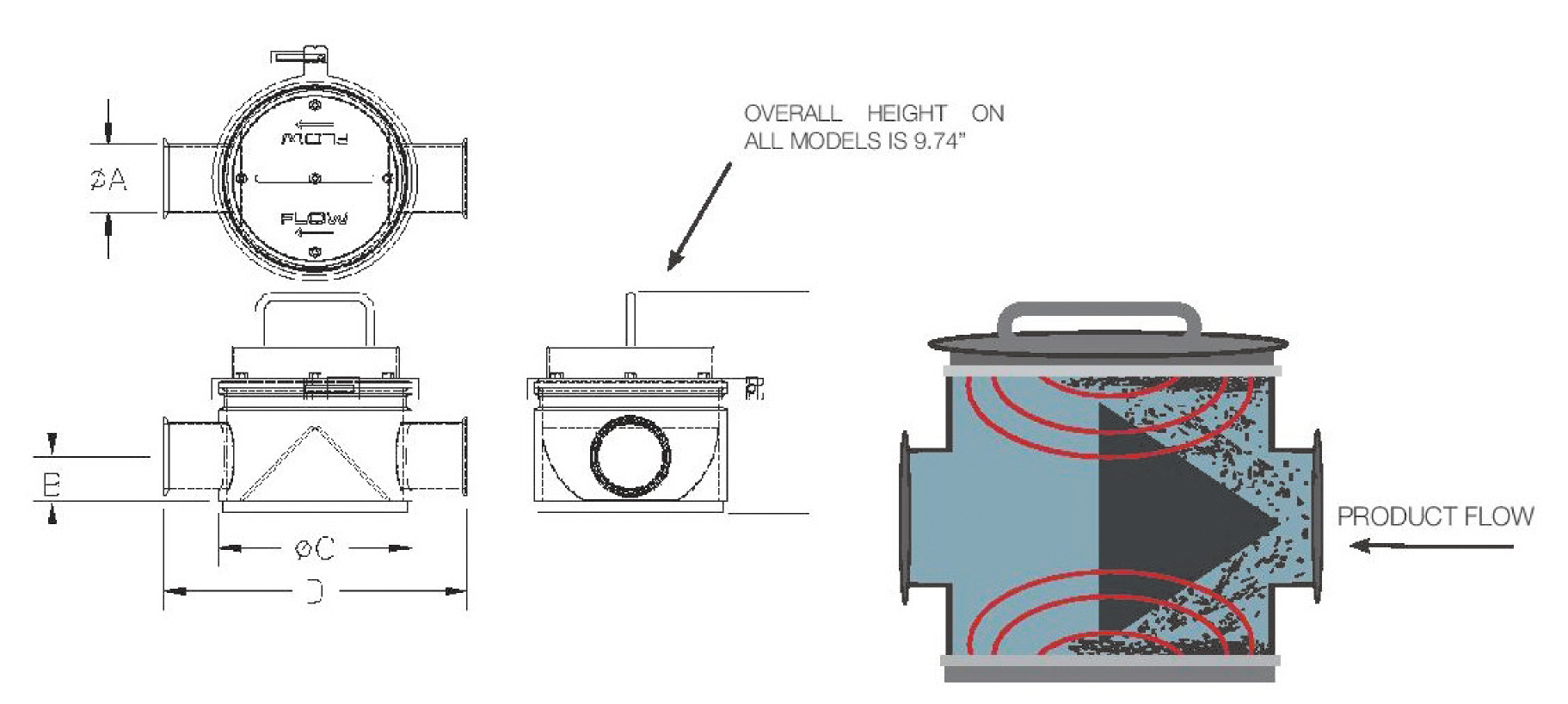

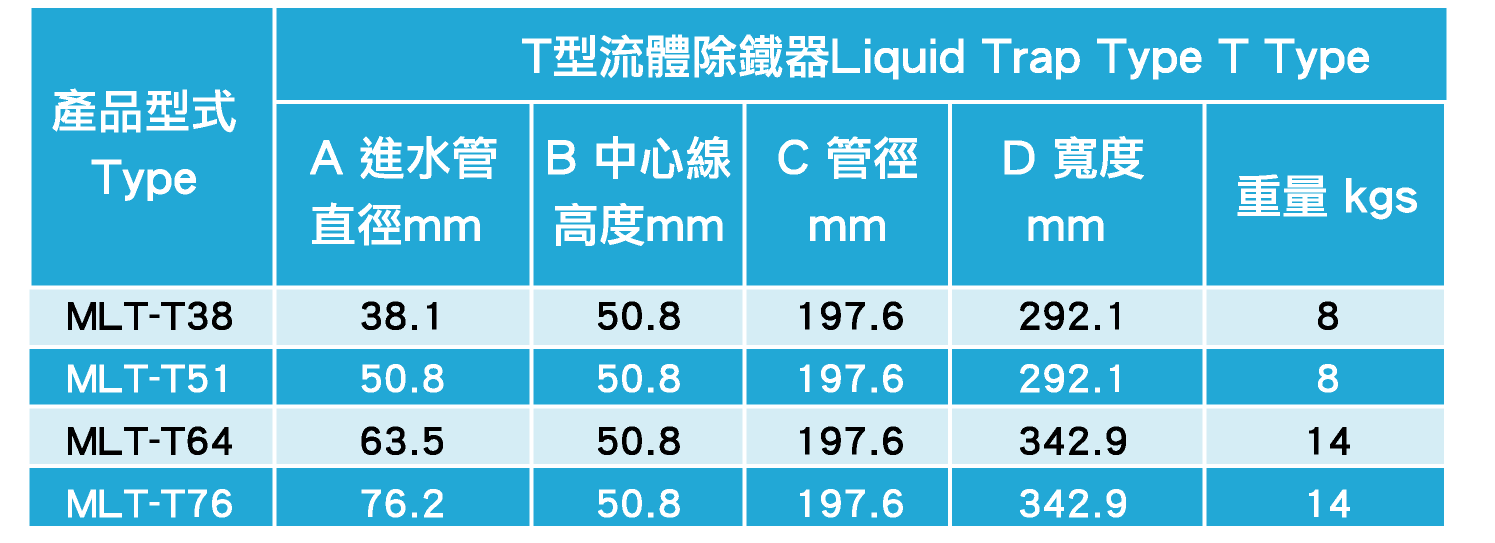

8. Liquid Trap Type T Type

T-plate design

Baffles in the chamber direct the product flow in the direction of the magnetic field, allowing ferrous contaminants to come into contact with the powerful magnetic plates. The capture area within the trap is enlarged and the product flow is slowed down, while the magnetic field capture capability of the entire magnetic plate is increased. Contamination can be easily cleaned by removing the clamp when the product flow is complete, lifting the magnetic plate and hand cleaning the surface.

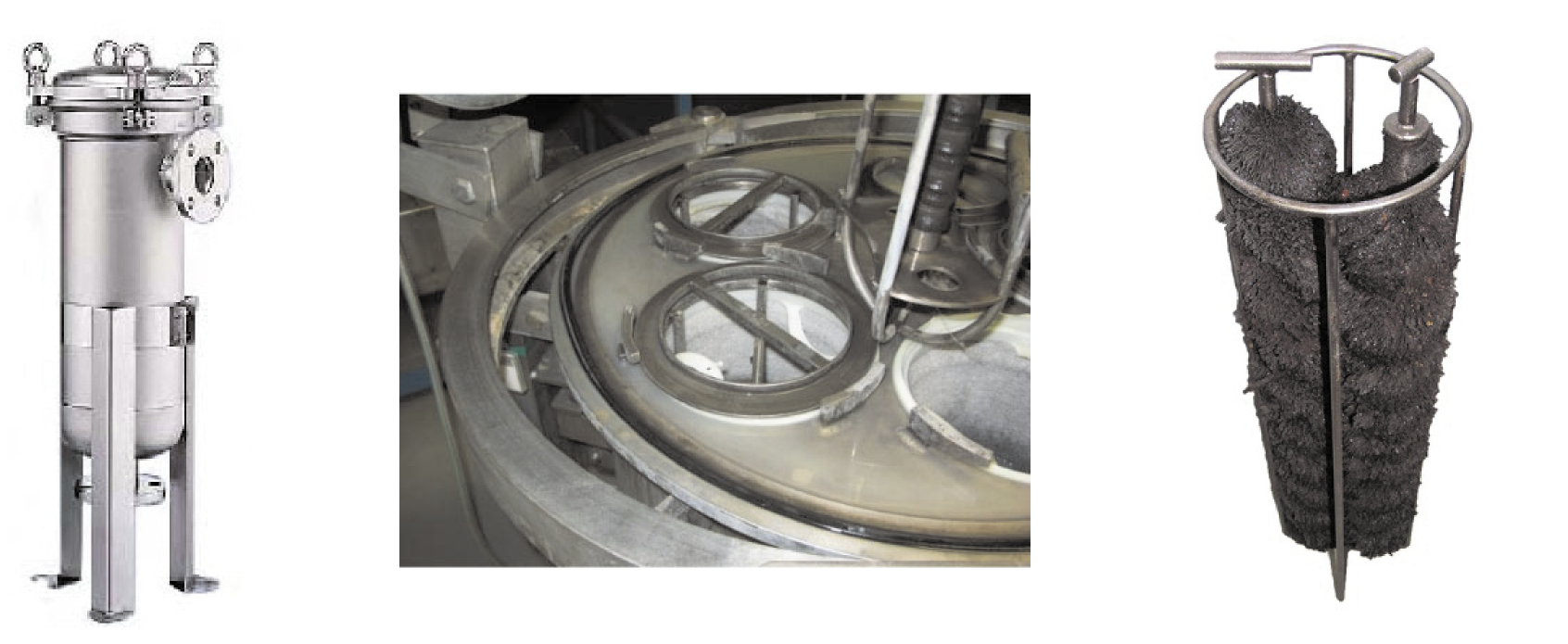

9. Filters

The filter is an indispensable filtering device in the system, its purpose is to filter the impurities in the medium, ensure the smooth flow of the medium and protect the important components inside the system. When the medium enters the filter cartridge

10.Overflow Type

The overflow filtration is to increase the water stroke as much as possible in a limited space through multiple turns of the water flow, so as to achieve a better filtration.