Description

Magnetic plates are designed for chutes and hanging over conveyed products. A magnetic plate mounted at the bottom of the chute will provide maximum protection as the product passes through a powerful magnetic circuit. A magnetic field is projected from the surface of the magnetic plate into the product and pulls ferrous contaminants onto the surface of the magnetic plate.

Structural features

1.Surface treatment: mirror polished, brushed or sandblasted, up to food grade requirements.

2.Material: stainless steel SUS304 or SUS316 or SUS316L.

3.Magnet: Hi gh-strength rare earth permanent ma gnet material. Surface ma gnetic field strength is above 1 500 - 1 0000 Gauss.

4.Working temperature: The working temperature of conventional products is lower than 80 °C, and the hi ghest temperature resistance can be provided for special

5.lnstallation method: bolts, rings, locks, hinges, etc. are fixed on the ma gnetic plate.

6.Cleaning method: provide common and easy-to-clean options.

7.Type: flush face type, spout face type, exposed pole type, suspended plate type.

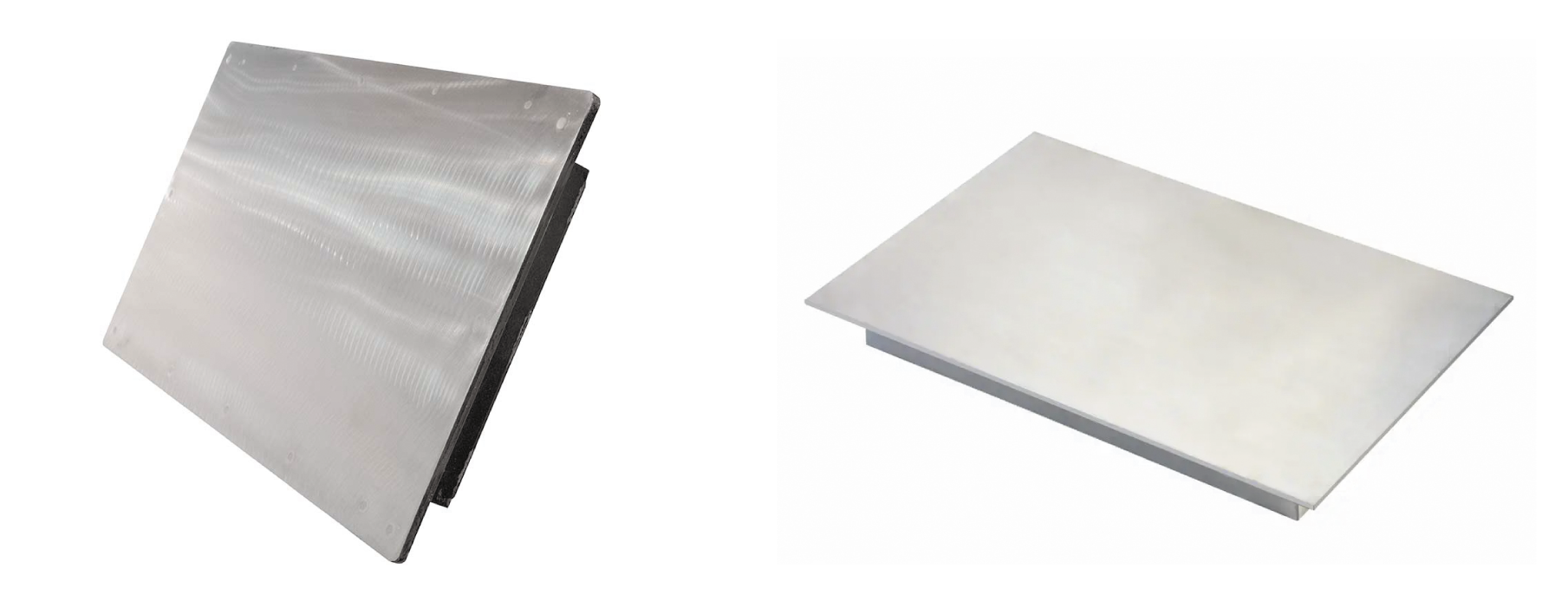

1. Flush Face Type(FF)

Flush magnetic plate provides optimum separation of contaminants when used on chutes or conveyor belts above the production line

can. When mounted above material, these magnetic plates provide continuous magnetic protection for downstream processing equipment.

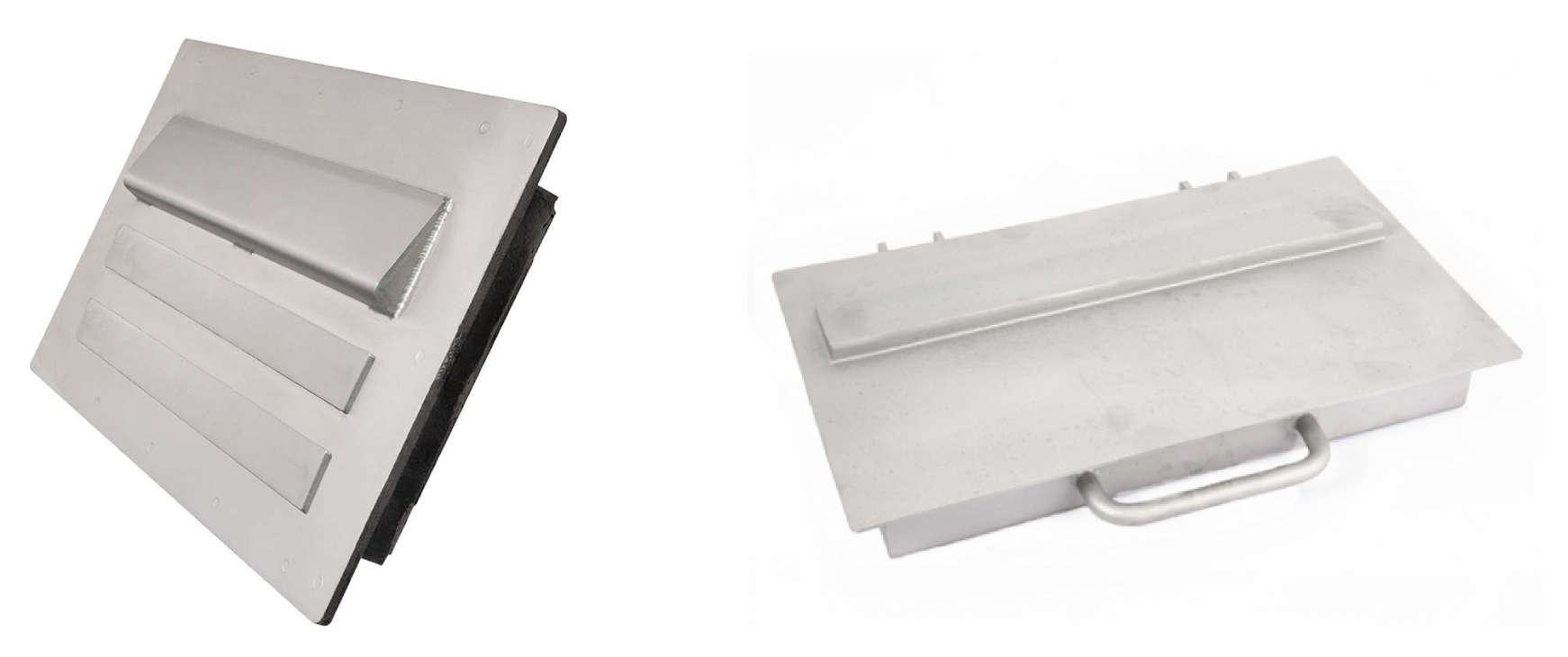

2.Tapered Step Type(TS)

Tapered stepped plate magnets are suitable for high density product applications. Specifically designed to keep ferrous contaminants on their solid tapered steps to prevent impurity iron and fines from being washed away, even when flowing rapidly.

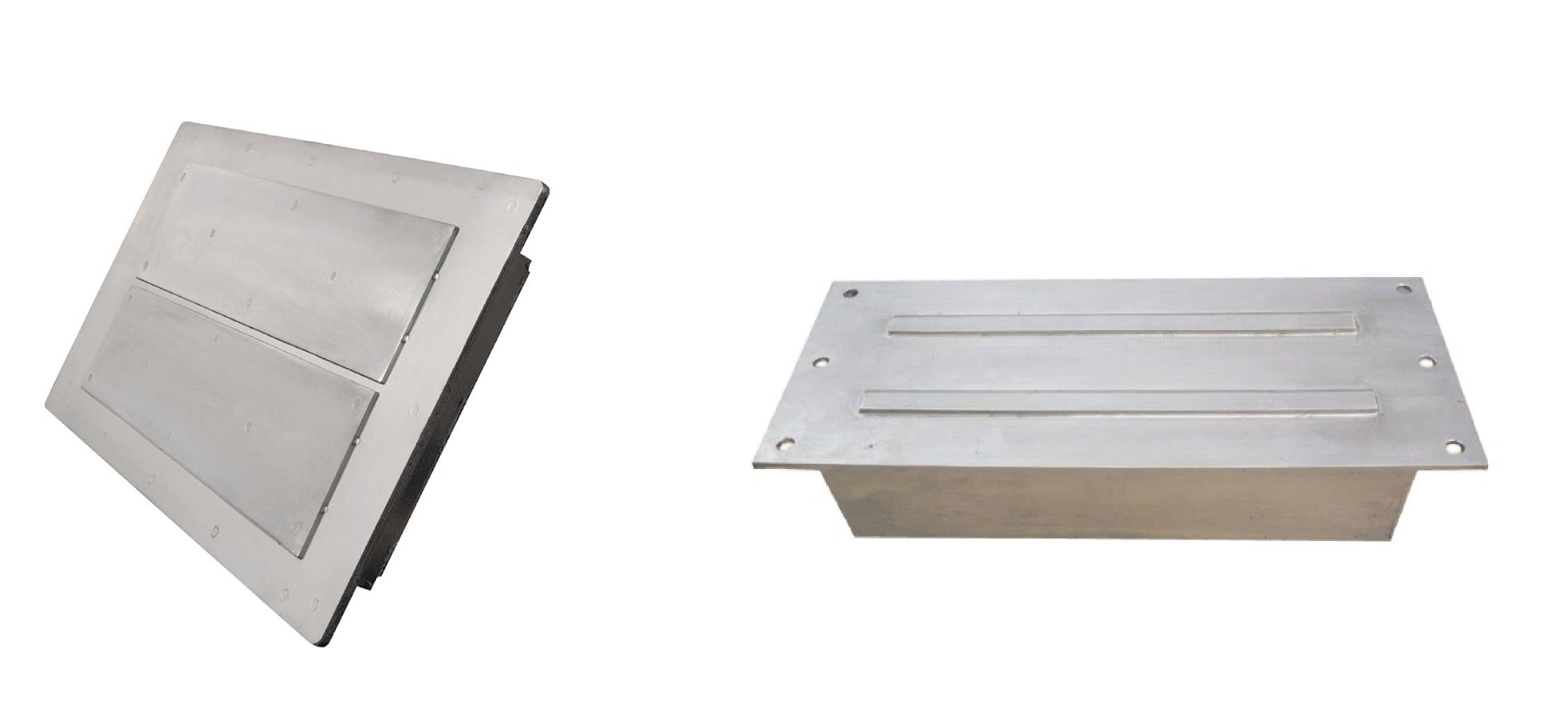

3.ExposedPole Type(EP)

Exposed pole plate magnets feature a two exposed plate design for high performance impurity metal separation in low to medium volume applications.

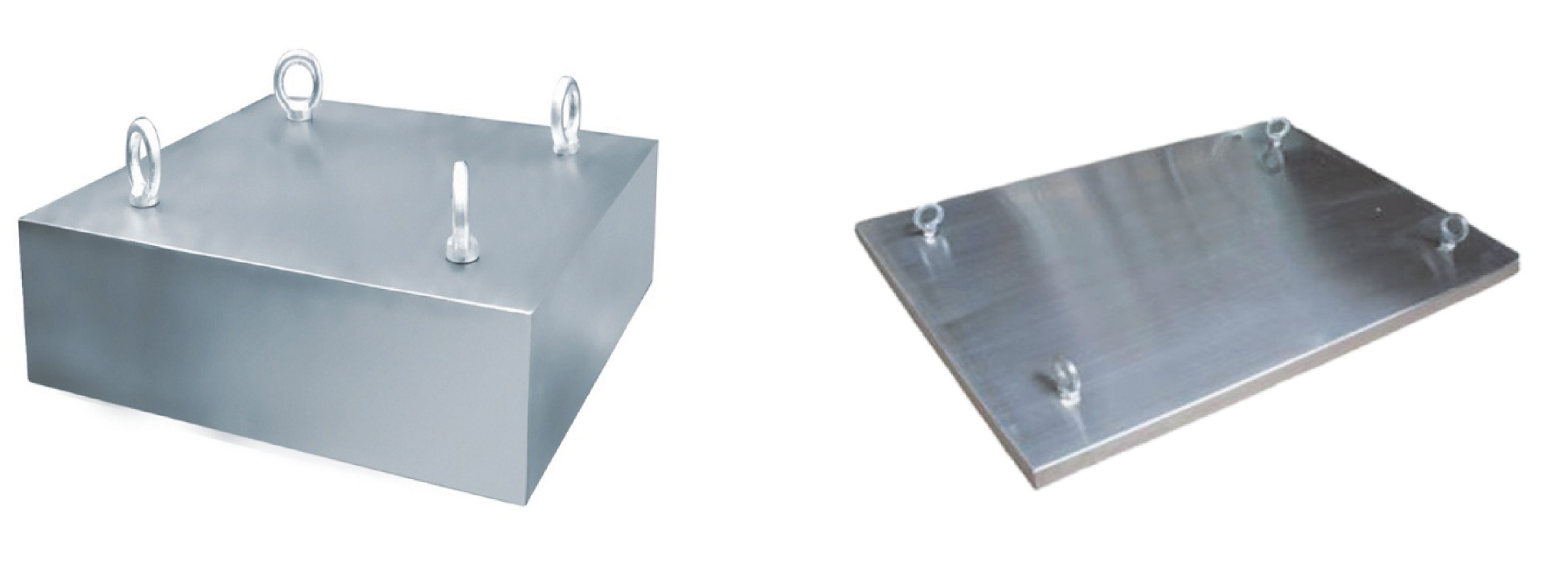

4. Suspended Plate Type (SP)

Suspended magnetic plates can be used in many industries to extract ferrous contaminants from production lines. Offer superior efficiency as they require no energy consumption and will not fail in the event of power fluc

5. Easy to clean

Magnetic plates can be equipped with a clean stripping tray for easy removal of trapped magnetic particles. There are longitudinal steel strips on the bottom of the cleaning strip disc (protecting the magnetic core steel plate), which prevent ferromagnetic particles captured during cleaning from jumping onto the magne.