Description

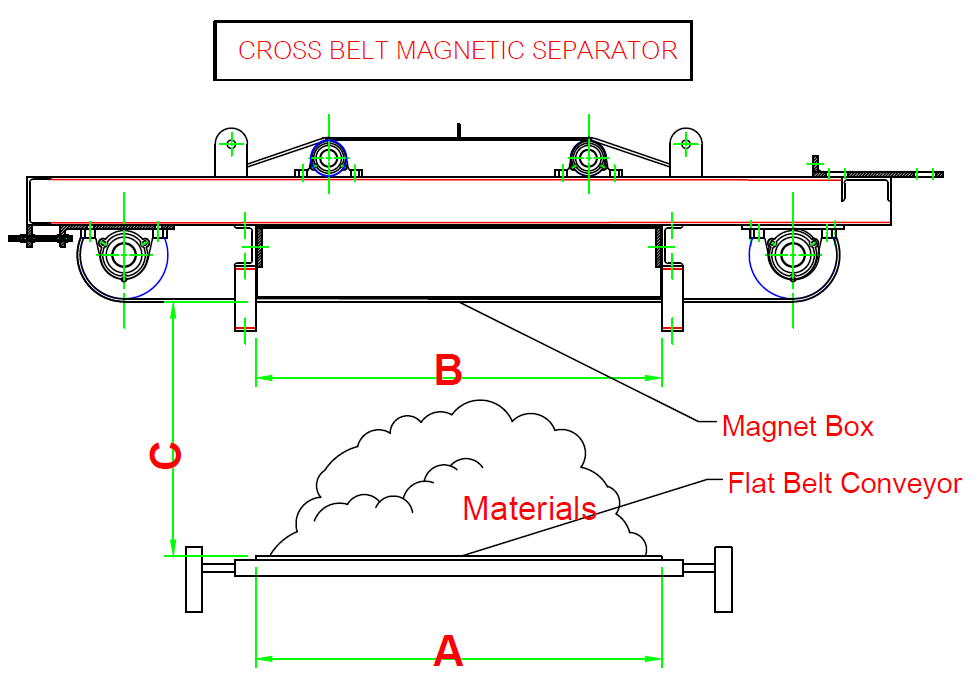

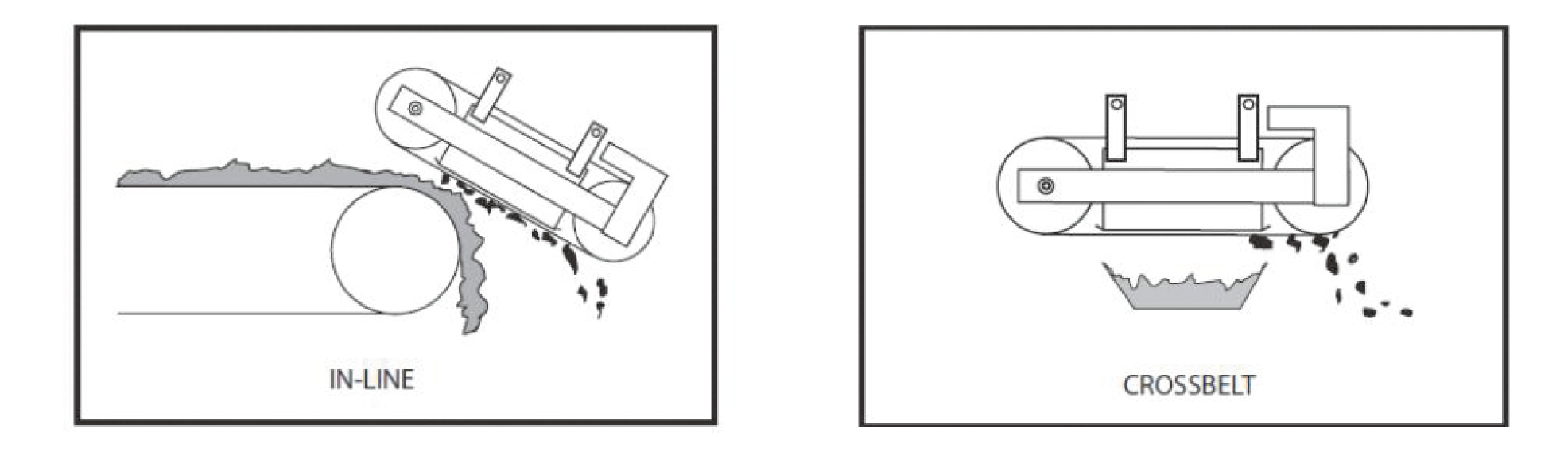

The material on the conveyor belt passes under the belt-type magnet, the ferrous metal is attracted to its surface, and the clean product continues along the conveyor belt as usual. A continuously moving belt carries the ferrous metal to one side of the conveyor, where it There it breaks away from the magnetic field and falls down.

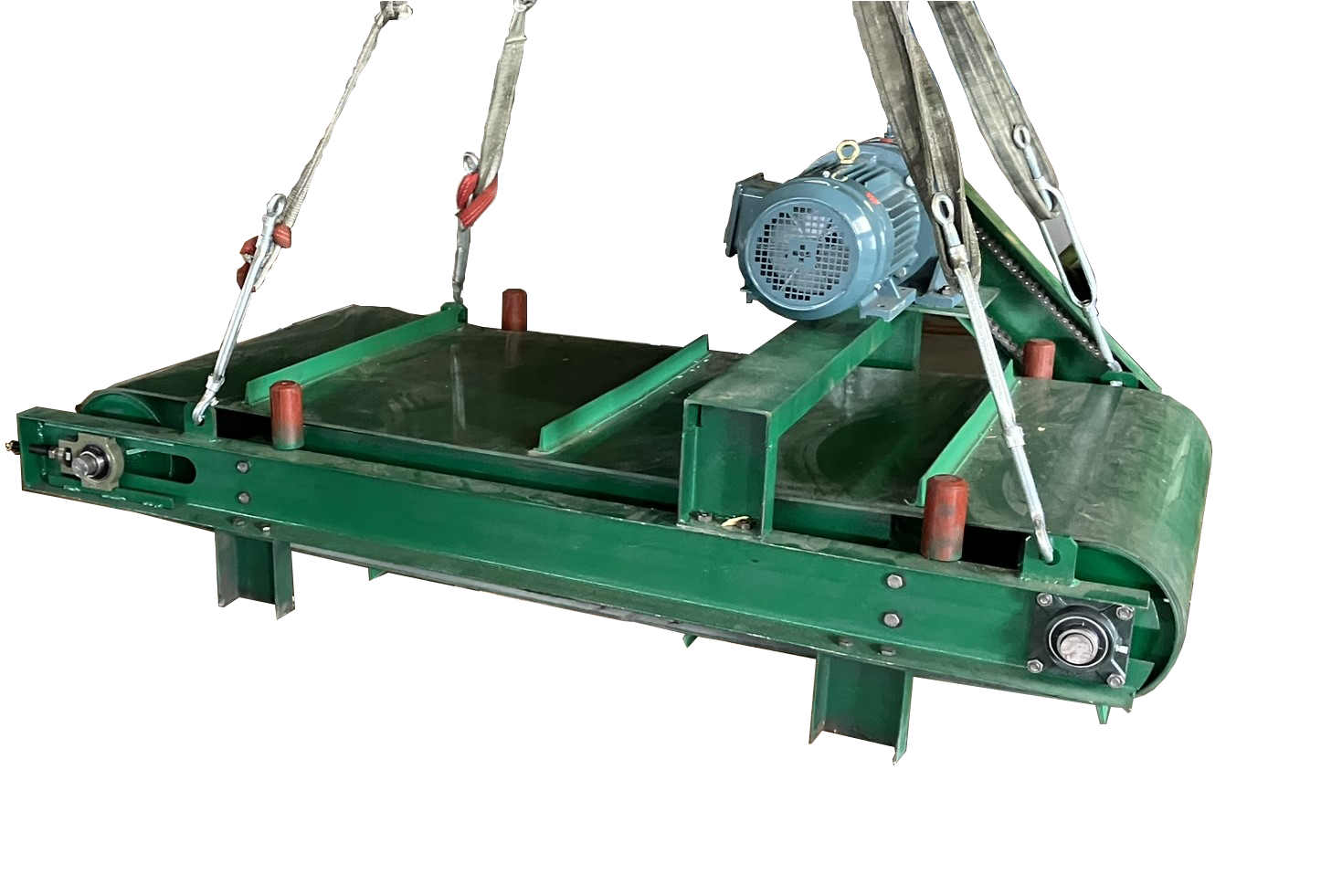

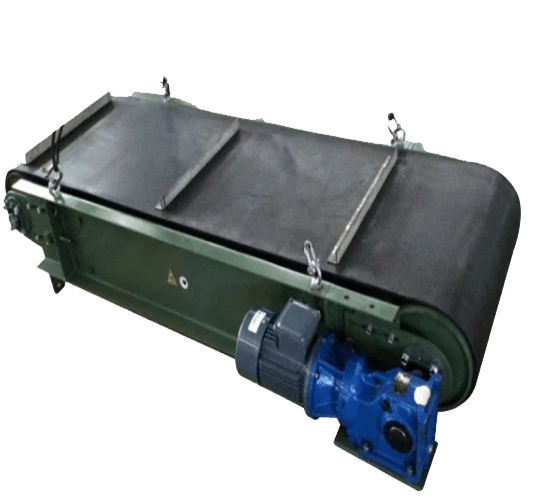

The self-unloading magnetic separator has a simple design, with two pulleys installed on the frame on both sides of the permanent magnet block. Self-unloading magnetic separators are designed for easy installation and can be mounted on a conveyor head pulley or, most commonly, on a conveyor belt.

The permanent magnets will retain metal impurities even during power outages and surges. Extended uptime, lower maintenance costs and a metal-free product.

Performance and installation

Suspension Method

Device Parameters

|

(mm) |

(mm) |

(mm) |

(kw) |

Applicable Conveyor Spoal (m/s) |

(mm) |

(kg) |

CBM-5 |

500 |

180 |

≤ 100 |

1.5 |

≤ 4.5 |

1650*835*940 |

600 |

CBM-6 |

600 |

200 |

≤ 125 |

1.5 |

≤ 4.5 |

1700*935*940 |

700 |

CBM-6.5 |

650 |

200 |

≤ 150 |

1.5 |

≤ 4.5 |

1750*985*940 |

700 |

CBM-8 |

800 |

250 |

≤ 200 |

2.2 |

≤ 4.5 |

1900*1140*960 |

800 |

CBM-10 |

1000 |

300 |

≤ 250 |

3.0 |

≤ 4.5 |

2140*1350*1010 |

1200 |

CBM-12 |

1200 |

350 |

≤ 300 |

4.0 |

≤ 4.5 |

2340*1550*1060 |

1400 |

CBM-14 |

1400 |

400 |

≤ 350 |

4.0 |

≤ 4.5 |

2540*1750*1060 |

1700 |

CBM-16 |

1600 |

450 |

≤ 400 |

5.5 |

≤ 4.5 |

3040*1550*860 |

2100 |

CBM-18 |

1800 |

500 |

≤ 450 |

7.5 |

≤ 4.5 |

3580*2450*1210 |

2200 |

CBM-20 |

2000 |

550 |

≤ 500 |

7.5 |

≤ 4.5 |

3800*2700*1300 |

2500 |