Description

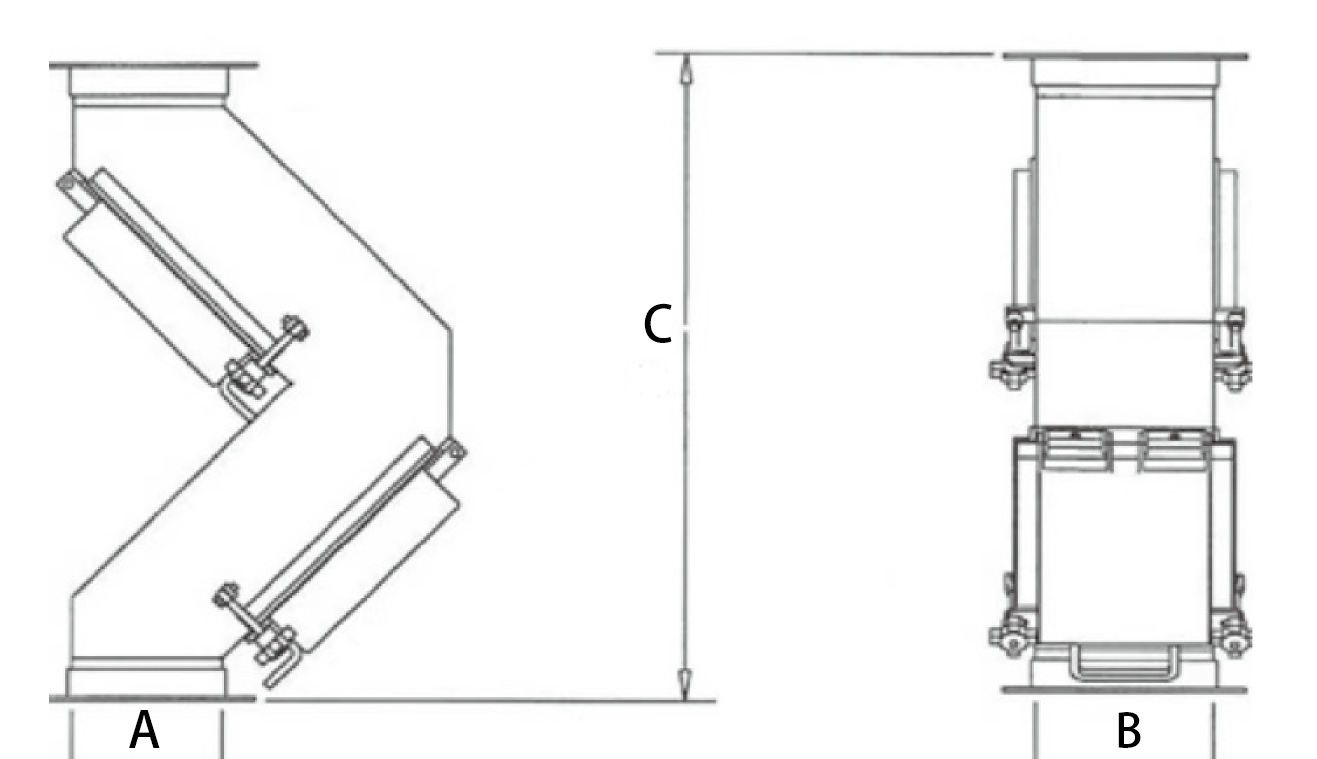

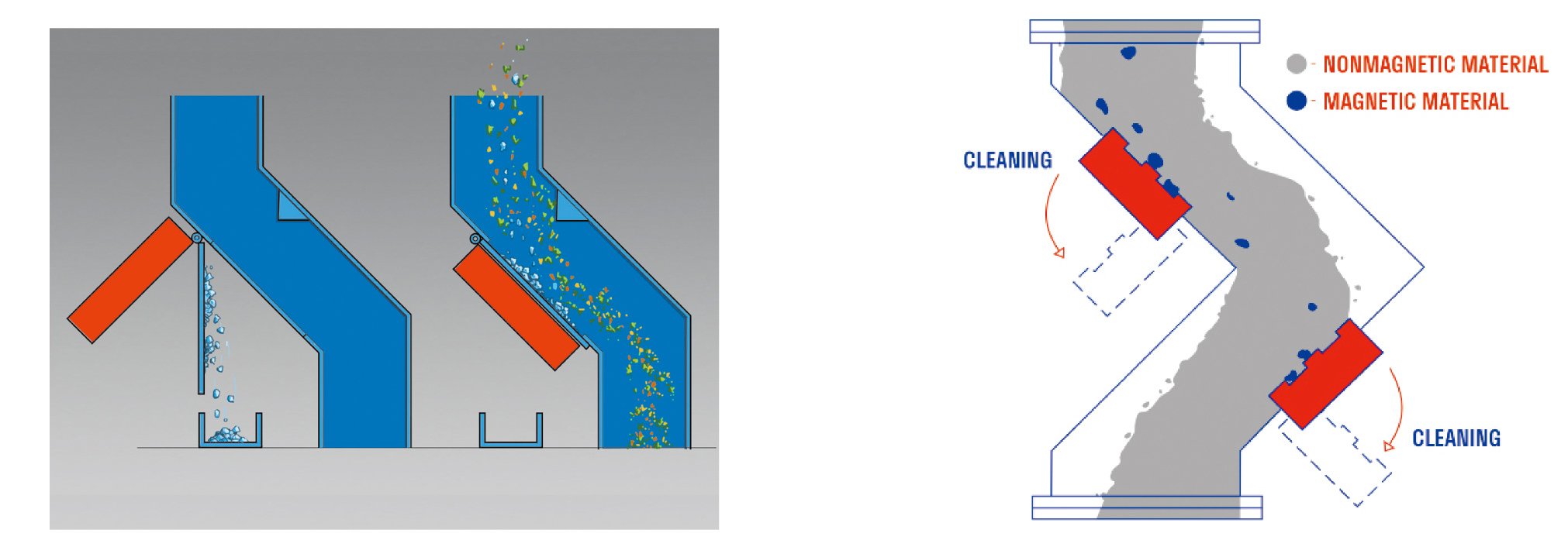

The magnetic hump usually consists of two plate magnets mounted in an offset housing and mounted in a vertical spout. When the product enters the case, it directly hits the surface of the first plate magnet, passes through the declination of the case and directly hits the surface of the second plate magnet. Specifically designed to provide excellent separation for bulky, poorly flowing or abrasive materials.

Structural features

1.Surface treatment: mirror polished, brushed or sandblasted, up to food grade requirements.

2.Shell material: stainless steel SUS304 or SUS316 or SUS316L.

3.Magnet: Rare earth permanent magnet or ferrite magnet. Surface magnetic field strength is 1500 - 10000 Gauss or above.

4.Working temperature: Ferrite:≤80°C, 100°C - 250°C.

NdFeB:≤80°C, 100°C - 220°C.

5.Cleaning method: provide common and easy-to-clean options.

6.Type: single hump, double hump, easy to clean.

Capture principle

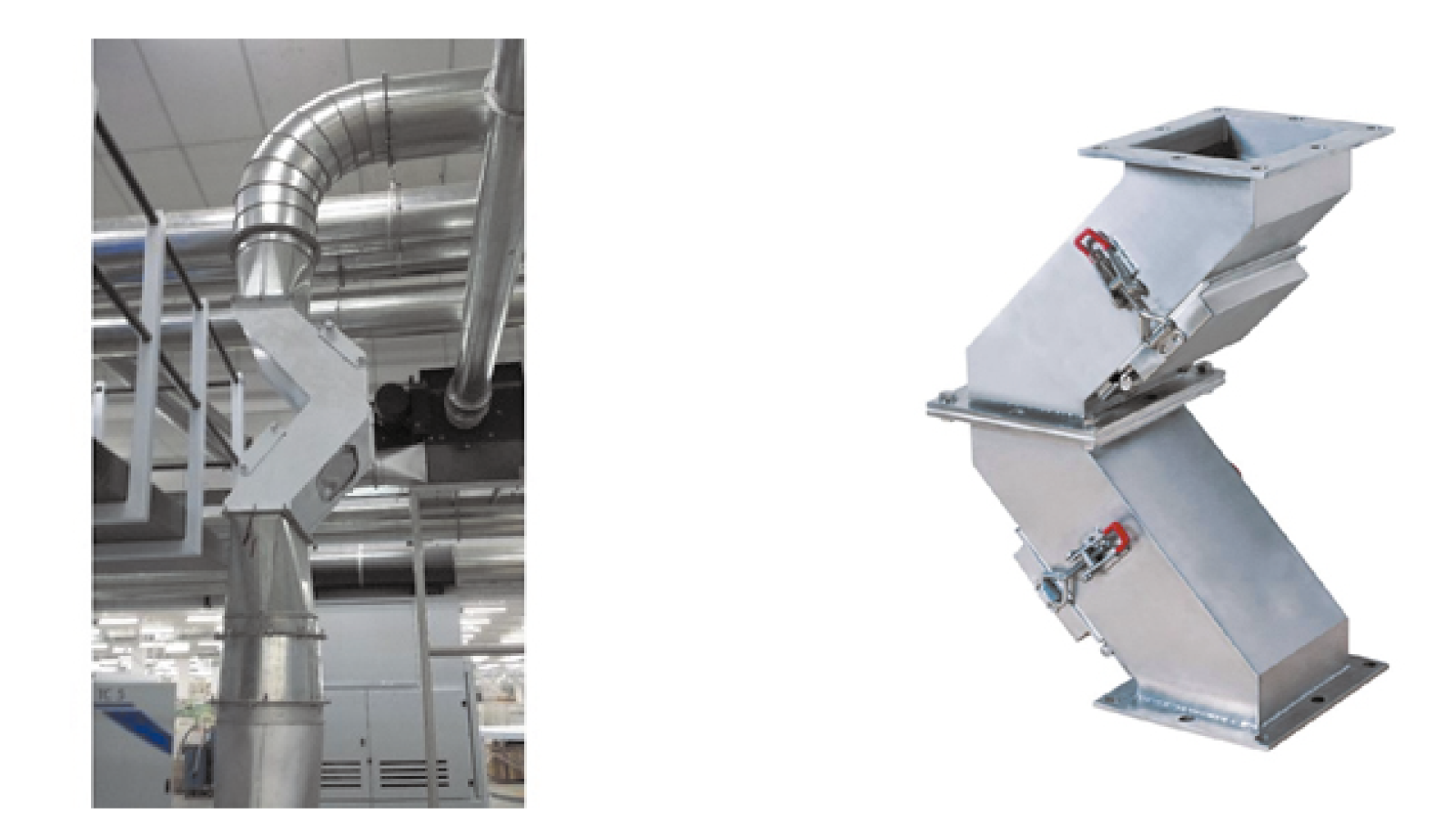

Application notes

1. single hump

2. Dual magnetic

3. Self-cleaning magnetic hump

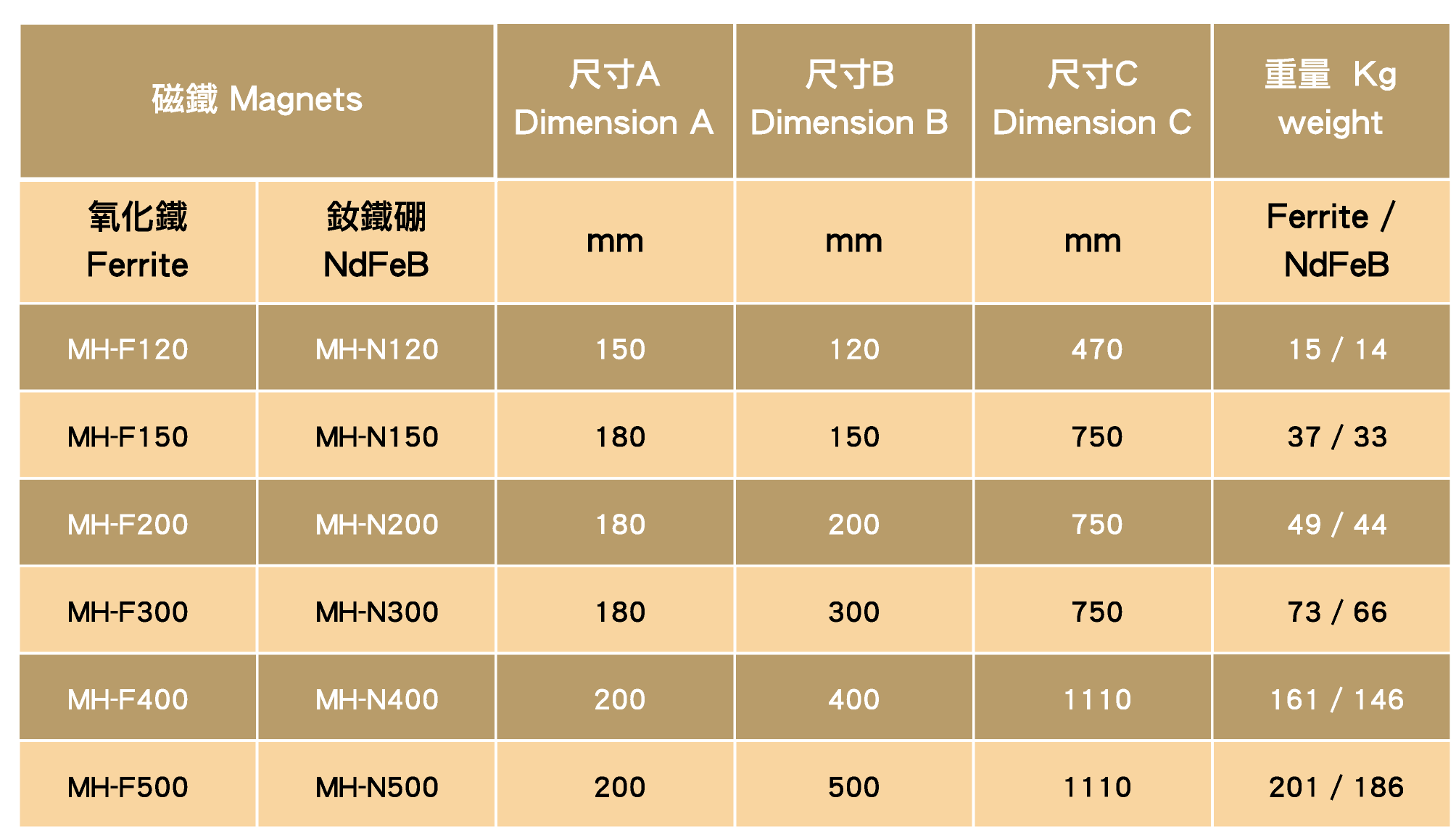

Device parameters