Description

Fully automatic magnetic separator for full cleaning without stopping the process. The magnetic separator is equipped with a pre-programmed PLC and can work independently or be connected to a central control room system for remote activation or monitoring. Auto-shuttle double, triple and quadruple-plus designs are also available for higher strength magnetic separation.

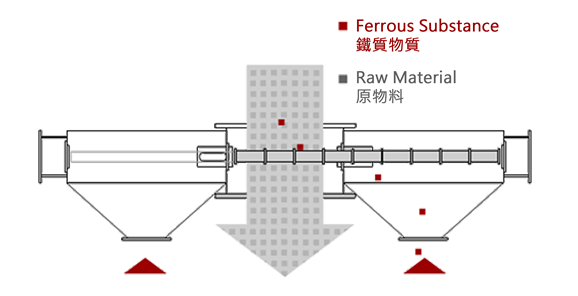

The magnetic rod remains in the processing chamber until the cleaning signal is sent. The compressed air is sent to each separation tube to clean the pollutants. The magnetic rod first passes through the product to perform filtering action, and then to the left and right cavities. Carry out slagging action for iron materials.

Structural features

The fully automatic magnetic separator helps to remove ferrous metal contaminants and magnetic stainless steel particles down to the micron level. To meet the requirements of various industry hygiene standards, automatic self-cleaning, suitable for all-weather operation, suitable for control room connections.

Magnetic properties: 3000, 5000, 7000, 9000, 10000, 12000, 13000 Gaussian design Performance readings: on outer tube surface

Magnetic material: rare earth NdFeB or ferrite magnet or SmCo magnet

Temperature: ≤80°C / up to 350°C

Pressure: +/- 0.2 bar

Housing: 316L grade stainless steel

Tube: 316L grade stainless steel

Seal: White gasket

Surface finish: Brushed inside and outside

PLC: Mitsubishi, Siemens.

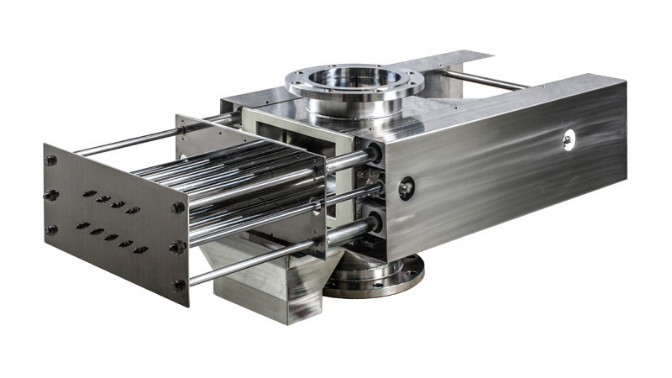

Structure

The base of the magnetic grid-shaped automatic separator is composed of a set of stainless steel magnetic grids superimposed on each other, and is equipped with a special magnetic field design. The magnetic sieve achieved in this way is in very close contact with the fluid material and is capable of capturing even the finest metallic impurities and guarantees a very high standard of separation. The compact design made of SUS304 stainless steel ensures simple and space-saving integration into existing production lines, while guaranteeing high durability and long service life of the entire system.

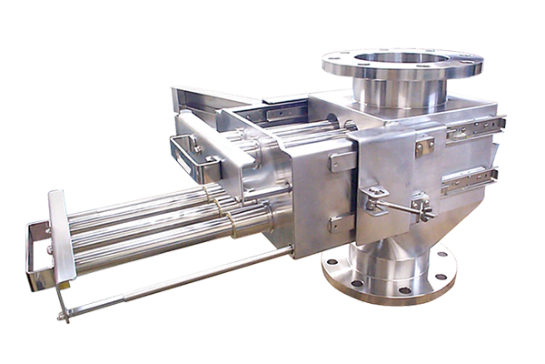

Fluid Magnetic Separator

In the automatic fluid separator, a set of magnetic rods with automatic cleaning function forms a complex flow-through magnetic field. The bar magnets are equipped with the strongest neodymium magnets, which, in combination with the through-current magnetic field, create the prerequisites for the successful separation of very fine ferromagnetic contaminants. The entire cleaning process of the separator is fully automatic.