Description

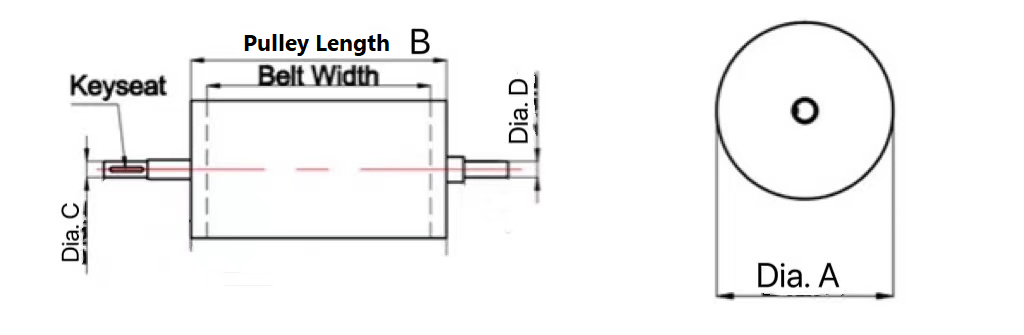

Magnetic pulleys are often composed of magnets, shafts and stainless steel housings. The magnet provides the magnetic field, the stainless steel shell acts to protect the magnet, and the shaft is the main component of the mechanical transmission.

Magnetic pulleys are always placed at the head of the conveyor belt to separate iron particles, iron filings, streaming iron and other ferromagnetic objects from the more bulk dry material flow.

Structural features

1.The drum body can be made of ferrite magnets or rare earth magnets, and the

magnetic field strength is 1500-8000GS.

2.The surface material is 304 or 316L stainless steel, which has good corrosion resistance.

3. No electricity is required to generate a magnetic field.

4. The special design of both ends of the pulley is to connect with the motor.

5. The shaft can be designed and manufactured according to the general bearing size,which is easy to install.

Application

Magnetic pulleys can be used to separate larger particles of iron impurities in granular materials and block materials, and is widely used in plastics, renewable resource recovery, wood deep processing, mineral processing, casting and other industries.

Device Parameters

1. Continuous self-cleaning design is suitable for automated production lines.

2. The surface material can be 304 or 316 stainless steel, which has good corrosion resistance.

3. Magnetic fields do not require electricity.

4. Magnetic field strength 1000-8000 Gs.

|