Description

MDS type magnetic drum (MDS type semi-magnetic drum structure and MP type parameters equivalent), more used for the purific ation of powdery, granular, small block materials, or the recycling of iron, to prevent the crusher, grinding machine, press damage and wear plays a reliable protective role.

Structural features

1. Continuous self-cleaning design is suitable for automated production lines.

2. The surface material can be 304 or 316 stainless steel, which has good corrosion resistance.

3. Magnetic fields do not require electricity.

4. Magnetic field strength 1000-8000 Gs.

Application

magnetic drums are mainly used in industries from iron ore, grain, sand, gravel, plastic, wood, waste, broken glass, etc.

Device Parameters

1. Continuous self-cleaning design is suitable for automated production lines.

2. The surface material can be 304 or 316 stainless steel, which has good corrosion resistance.

3. Magnetic fields do not require electricity.

4. Magnetic field strength 1000-8000 Gs.

|

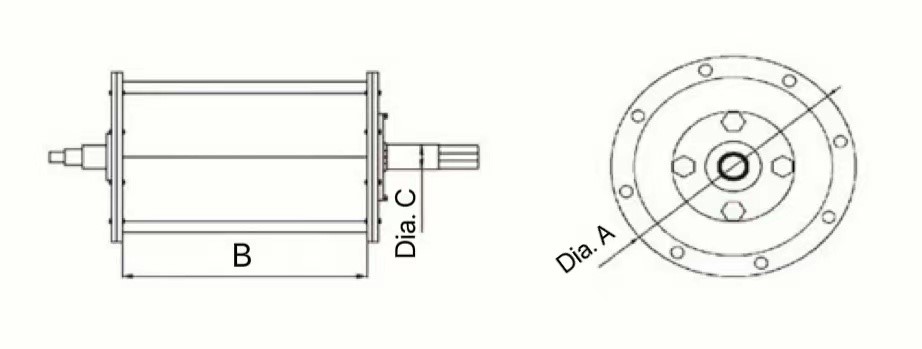

Type

|

Drum Diameter(mm)

|

Drum length

|

Magnetic Intensity

|

Suitable Belt Speed

|

Material Thickness ≤ (mm)

|

Bearing seat spacing

|

Weight(kg)

|

|

MDS-22/50 |

220 |

410 |

1000-8000 |

≤2.5m/s |

40 |

560 |

40 |

|

MDS-27/50 |

273 |

510 |

60 |

660 |

55 |

||

|

MDS-32/60 |

320 |

620 |

60 |

770 |

80 |

||

|

MDS-40/60 |

400 |

830 |

80 |

980 |

100 |

||

|

MDS-50/60 |

500 |

1030 |

80 |

1180 |

160 |

||

|

MDS-60/60 |

600 |

1230 |

100 |

1380 |

240 |

||

|

MDS-80/80 |

800 |

1230 |

120 |

1380 |

400 |

||

|

MDS-80/100 |

800 |

1430 |

140 |

1580 |

800 |